Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

2026 Top Foot Valves Types for Efficient Fluid Control Solutions?

In industries that handle fluids, the importance of reliable foot valves cannot be overstated. "Foot valves are critical for maintaining system efficiency and preventing backflow," says John Smith, a leading expert in fluid control systems. His insight highlights the need for the right type of valve in various applications.

Foot valves serve as the first line of defense in fluid systems. They allow liquids to flow in one direction while blocking backflow effectively. When these valves fail, it can lead to costly downtime and system inefficiencies. Selecting the best foot valve type is essential for smooth operation.

Yet, the market offers various options, each with distinct advantages and limitations. Proper knowledge of these types can lead to better performance. However, not all industries research adequately, risking their operations. Evaluating the needs and capabilities of each foot valve is not always easy but necessary for optimized fluid control.

Overview of Foot Valves and Their Importance in Fluid Systems

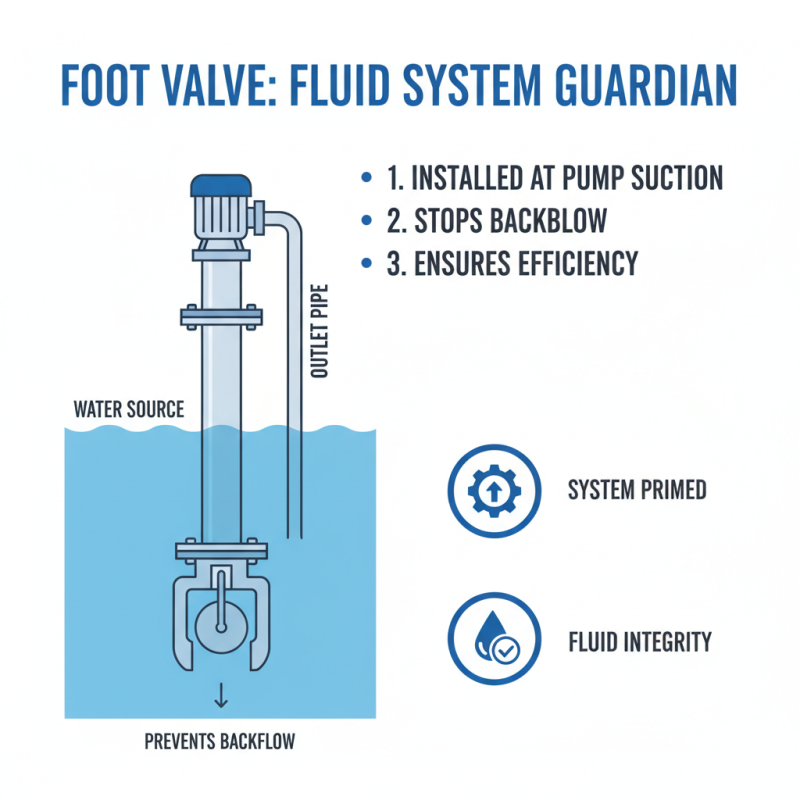

Foot valves play a critical role in fluid systems. They are often installed at the bottom of pump suction lines. Their purpose is to prevent backflow when the pump is turned off. This keeps the system primed and ready for operation. A well-functioning foot valve ensures efficiency and fluid integrity.

Choosing the right foot valve type can be challenging. Various designs exist, each with unique features. Some are more suited for certain applications than others. This adds complexity when selecting the ideal model. Additionally, improper installation can lead to performance issues. Regular maintenance is needed to prevent wear and tear.

Understanding foot valves is essential for anyone working with fluid systems. Their importance often goes unnoticed. However, when they fail, the consequences can be significant. It's crucial to evaluate the specific needs of the system. Choosing the right type can enhance efficiency and reliability in fluid control.

Different Types of Foot Valves for Various Applications

Foot valves play a crucial role in fluid control systems. They are essential in various applications, particularly in water pumping and irrigation. The choice of foot valve type can affect efficiency and performance. Common types include ball foot valves, spring check valves, and diaphragm valves. Each type has unique benefits and drawbacks.

Ball foot valves are popular for their reliable sealing capabilities. They are effective in preventing backflow in suction lines. Yet, they may require regular maintenance to avoid wear. Spring check valves, on the other hand, are less prone to clogging but can struggle with high-viscosity fluids. Meanwhile, diaphragm valves provide excellent control but can be more complex to install.

Tips: Regularly inspecting foot valves can prolong their lifespan. Look out for signs of wear, such as corrosion or leaks. Choosing the right foot valve type can enhance fluid dynamics. Efficiency often correlates with valve selection especially in high-demand environments. Evaluating specific operational needs is key in decision-making. Make informed choices to prevent unnecessary downtime.

2026 Top Foot Valves Types for Efficient Fluid Control Solutions

This chart illustrates the distribution of different types of foot valves and their applications. The data represents the estimated market share for each type of foot valve in various industrial applications.

Key Features to Consider When Selecting a Foot Valve

When selecting a foot valve, several key features stand out. First, consider the material. Foot valves are often made of metal or plastic. The choice impacts durability and performance. Metal valves may resist corrosion better but can be heavier. Plastic variants are lightweight but may crack under stress.

Flow rate is another critical feature. A valve with a higher flow rate can manage larger volumes. Check the specifications to ensure it meets your needs. Look for design elements that facilitate easy maintenance. Valves with removable screens provide easier cleaning options, extending their lifespan.

Tip: Always assess the installation environment. High-pressure areas require robust designs. For low-pressure setups, lightweight valves could suffice. Reflect on how often you will need maintenance. Neglecting this can lead to unexpected costs over time.

Lastly, ensure proper sizing is addressed. An improperly sized valve can cause operational issues. It’s essential to take measurements accurately. Getting this right can save you from future headaches.

2026 Top Foot Valves Types for Efficient Fluid Control Solutions

| Foot Valve Type | Material | Connection Type | Max Pressure (PSI) | Key Features |

|---|---|---|---|---|

| PVC Foot Valve | PVC | Threaded | 150 | Corrosion-resistant, lightweight |

| Bronze Foot Valve | Bronze | Flanged | 200 | Durable, good flow performance |

| Stainless Steel Foot Valve | Stainless Steel | Welded | 300 | Highly resistant to corrosion and rust |

| Cast Iron Foot Valve | Cast Iron | Threaded | 250 | Sturdy, suitable for heavy-duty applications |

Benefits of Using Foot Valves for Efficient Fluid Control

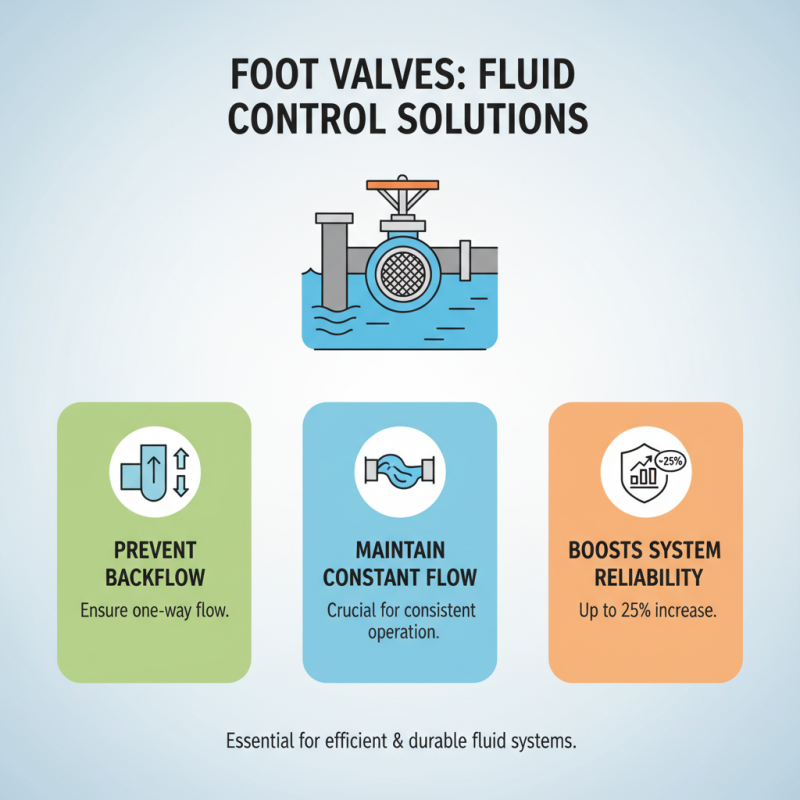

Foot valves play a crucial role in efficient fluid control solutions. They help prevent backflow and maintain a constant flow, which is essential in many applications. Studies indicate that using foot valves can increase system reliability by up to 25%. This statistic illustrates the significant impact these devices have on system efficiency and longevity.

One key benefit is their ability to enhance pump performance. A properly installed foot valve reduces the risk of losing prime in a pump system. Inadequate priming affects flow rates and increases energy costs. Installing foot valves correctly can lower energy consumption by approximately 15%. However, it is vital to select the right type of foot valve for your specific application to avoid performance issues.

Another aspect to consider is maintenance. Foot valves require regular checks to ensure functionality. A failure to maintain them can lead to costly repairs, and downtime. In some industries, up to 30% of operational costs can stem from equipment failures. Evaluating foot valves alongside other components in fluid systems helps pinpoint potential risks and areas for improvement. While foot valves are a small component, their effects can be significant.

Best Practices for Maintenance and Troubleshooting Foot Valves

Foot valves play a critical role in fluid systems. Regular maintenance is essential to ensure their efficiency. Neglecting routine checks can lead to major issues. Inspect the valve for signs of wear and tear. This can include corrosion or sediment buildup. Such factors can disrupt flow.

Troubleshooting foot valves requires attention to detail. If you notice irregularities in fluid flow, check for blockages. Sometimes a simple cleaning can resolve the issue. Listen for unusual noises during operation. They often indicate deeper problems. Take note of any leaks. Addressing them promptly can prevent further damage.

Remember, prevention is key. Consistent maintenance extends the life of foot valves. Replace components that show serious wear. This will help maintain optimal performance in the long run. If issues persist, seek professional advice. While DIY approaches can save money, they might miss critical issues. Always reflect on the valve's condition. A proactive mindset leads to better fluid control solutions.

Related Posts

-

Understanding Flow Valves: How They Optimize Fluid Control with 30% Efficiency Gains in Industry

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs

-

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

-

What Are Gate Valves and How Do They Work?

-

Top 10 Globe Valves: Essential Choices for Optimal Flow Control Solutions