Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

The Best Fittings Valves for Your Plumbing Needs?

Choosing the right fittings valves can greatly influence your plumbing system. These components are essential for controlling water flow. They connect pipes and fittings, ensuring a secure and leak-proof system.

When selecting fittings valves, consider your specific needs. Different materials and designs suit various applications. For example, brass fittings valves offer durability, while PVC ones are lightweight and cost-effective. Understanding your requirements will help you make informed choices.

However, not all fittings valves are created equal. Quality varies across brands and types. Some may wear out quickly or become corroded. It's crucial to research and read reviews. Investing in high-quality fittings valves can save you from future headaches. Reflect on your plumbing needs and choose wisely for a reliable installation.

Understanding the Importance of Choosing the Right Fittings Valves

Choosing the right fittings valves is essential for effective plumbing. Inaccurate valve selection can lead to leaks and costly repairs. According to a report by the Plumbing Foundation, improper fittings account for 27% of plumbing failures. These figures highlight the importance of understanding your specific needs.

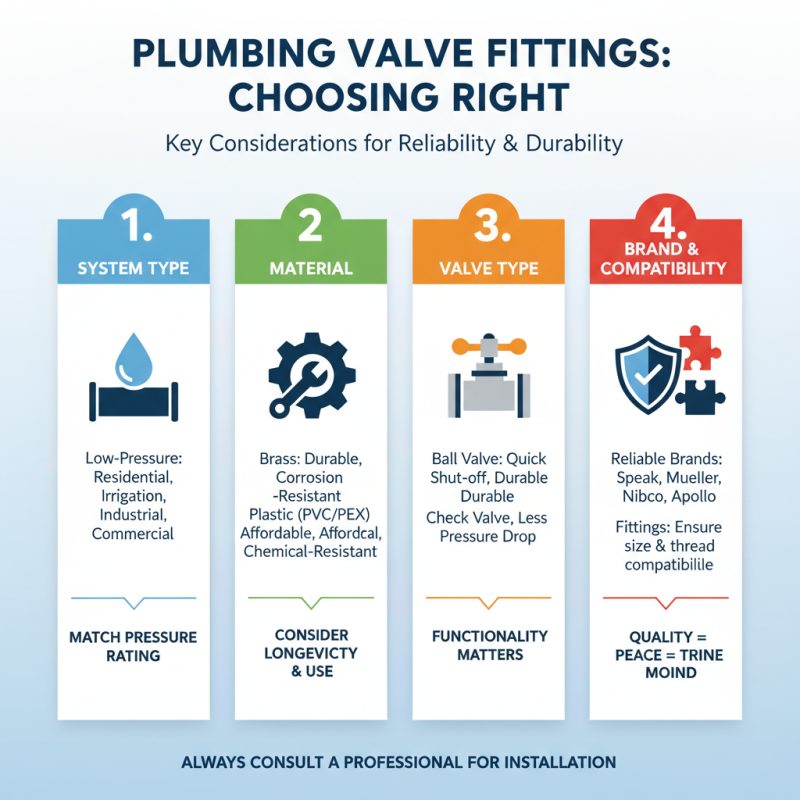

Different applications require different valves. For instance, a ball valve offers a tight seal but might not perform well in high-pressure situations. Conversely, gate valves are excellent for regulating flow, but they may have issues with wear over time. Plumbing professionals recommend assessing the environment and fluid type when choosing valves. If not considered, you might encounter unexpected challenges.

Ultimately, not all fittings valves are created equal. Quality materials matter. Brass valves are durable but can corrode in certain water conditions. Plastic valves, while lightweight, may not withstand high temperatures. Regular maintenance is crucial. Neglecting this aspect can lead to failures, which is something many homeowners ignore until it’s too late. Making informed decisions is key to avoiding these pitfalls.

The Best Fittings Valves for Your Plumbing Needs

| Valve Type | Material | Pressure Rating | Application | Connection Type |

|---|---|---|---|---|

| Gate Valve | Brass | 150 psi | Water Supply | Threaded |

| Ball Valve | PVC | 200 psi | Residential Plumbing | Socket Weld |

| Check Valve | Stainless Steel | 250 psi | Backflow Prevention | Flanged |

| Globe Valve | Bronze | 150 psi | Flow Regulation | Threaded |

| Peg Valve | Plastic | 100 psi | Low-Pressure Systems | Compression |

Types of Fittings Valves Commonly Used in Plumbing Systems

In plumbing systems, choosing the right fittings valves is crucial. There are several types commonly used. Each serves a specific purpose. The most common types include gate valves, ball valves, and globe valves.

Gate valves are typically utilized in large pipes. They allow for full flow when open, creating minimal resistance. However, they can be slow to open and close. Ball valves, on the other hand, are quick and effective. They provide a tight seal and can handle high pressure. Globe valves are used when flow regulation is needed. They restrict flow and can present challenges in maintaining pressure.

**Tip:** Always consider the flow rate before selecting a valve. An incorrect choice can lead to inefficiencies.

You’ll also want to reflect on materials. Brass and PVC fittings work for many applications, but they aren't always compatible. Avoid mixing materials without consulting experts.

**Tip:** Regular maintenance of valves can prevent leaks and failures. Check them periodically for wear and functionality.

The Best Fittings Valves for Your Plumbing Needs

Key Features to Consider When Selecting Fittings Valves

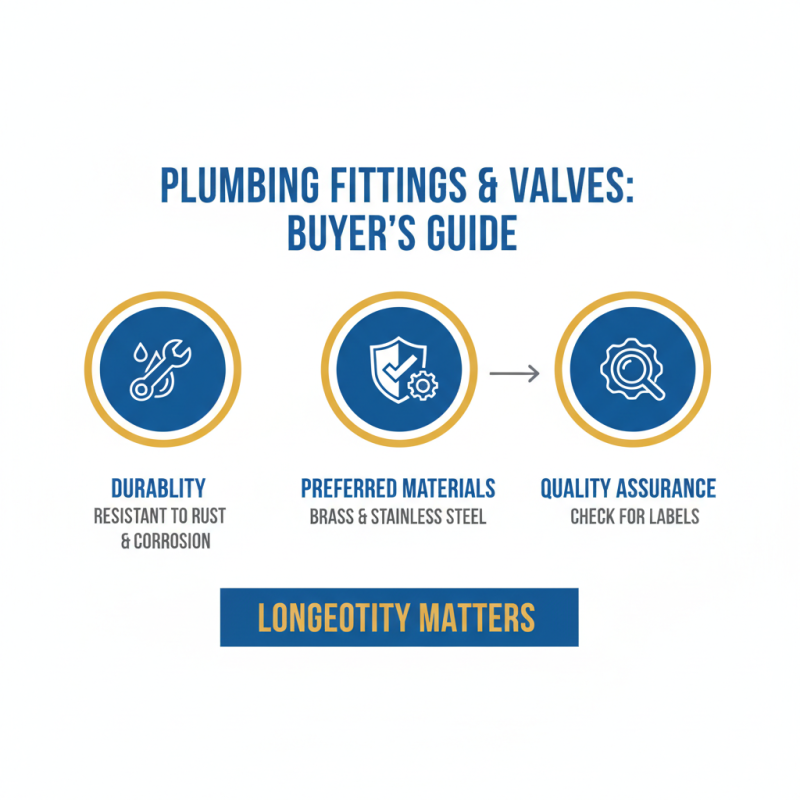

When selecting fittings valves for plumbing needs, several key features come into play. Durability is critical. Look for materials resistant to rust and corrosion. Brass and stainless steel are often preferred due to their longevity. However, manufacturers may cut corners. Always check for quality assurance labels.

Sizing also matters. Ensure the valve fits your pipe diameter. Ill-fitting valves can cause leaks or other plumbing issues. Measure carefully before purchase. Some people overlook this step and face problems later on. Compatibility with existing systems is vital. A valve that doesn't match your fittings may lead to significant complications.

Flow rate is another essential factor. Different valves control the speed of water flow. A higher flow rate might be required for specific applications. Yet, too fast can lead to wear and tear. Users should find a balance. Finally, ease of installation should not be neglected. Many valves come with user-friendly designs. Yet, some still require professional help. Assess your skills honestly to avoid headaches later.

Top Brands and Their Best-Selling Fittings Valves

Choosing the right fittings valves for plumbing is crucial. Many brands offer reliable options. It's essential to understand your specific needs before purchasing. Some valves are designed for low-pressure systems while others handle high-pressure applications. You should consider the materials used, such as brass or plastic, as they affect durability.

Make sure to check the reviews. Customer feedback can reveal a lot about the product's performance. Some fittings may leak or break down faster than others. It’s worth investing in a valve that is proven to stand the test of time. Look for models with a warranty. This can provide peace of mind for your plumbing projects.

Tips: Always measure your pipes before selecting valves. A small mistake in size can lead to major issues. It’s also advisable to consult an expert if you're unsure. DIY could save money, but mistakes can be costly. Relying solely on budget options might backfire. Quality often outweighs the initial cost.

Maintenance Tips for Ensuring Longevity of Plumbing Fittings Valves

Maintaining plumbing fittings valves is crucial for their longevity. Regular inspections can help identify problems early. Look for leaks or signs of corrosion. A small drip can lead to bigger issues over time.

Cleaning valves is essential. Use a damp cloth to wipe away dirt. If you notice mineral buildup, a vinegar solution can help. This can restore the valve's functionality. Remember not to use high-pressure water. It might cause damage or exacerbate wear.

Consider replacing washers and seals periodically. These parts can wear out faster than the valve itself. Ignoring this can lead to leaks. It’s an easy fix that prevents larger repairs. Take a moment to check your valves. You might find they require more attention than you thought.

Related Posts

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs

-

Ultimate Checklist for Choosing the Right Flanges and Fittings for Your Project

-

How to Achieve Perfect Weld Bend Specifications for Your Projects

-

The Future of Steel and Fittings Innovation Trends Data and Best Practices

-

Top 10 Gate Fittings for Your Home Security Needs?

-

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025