Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

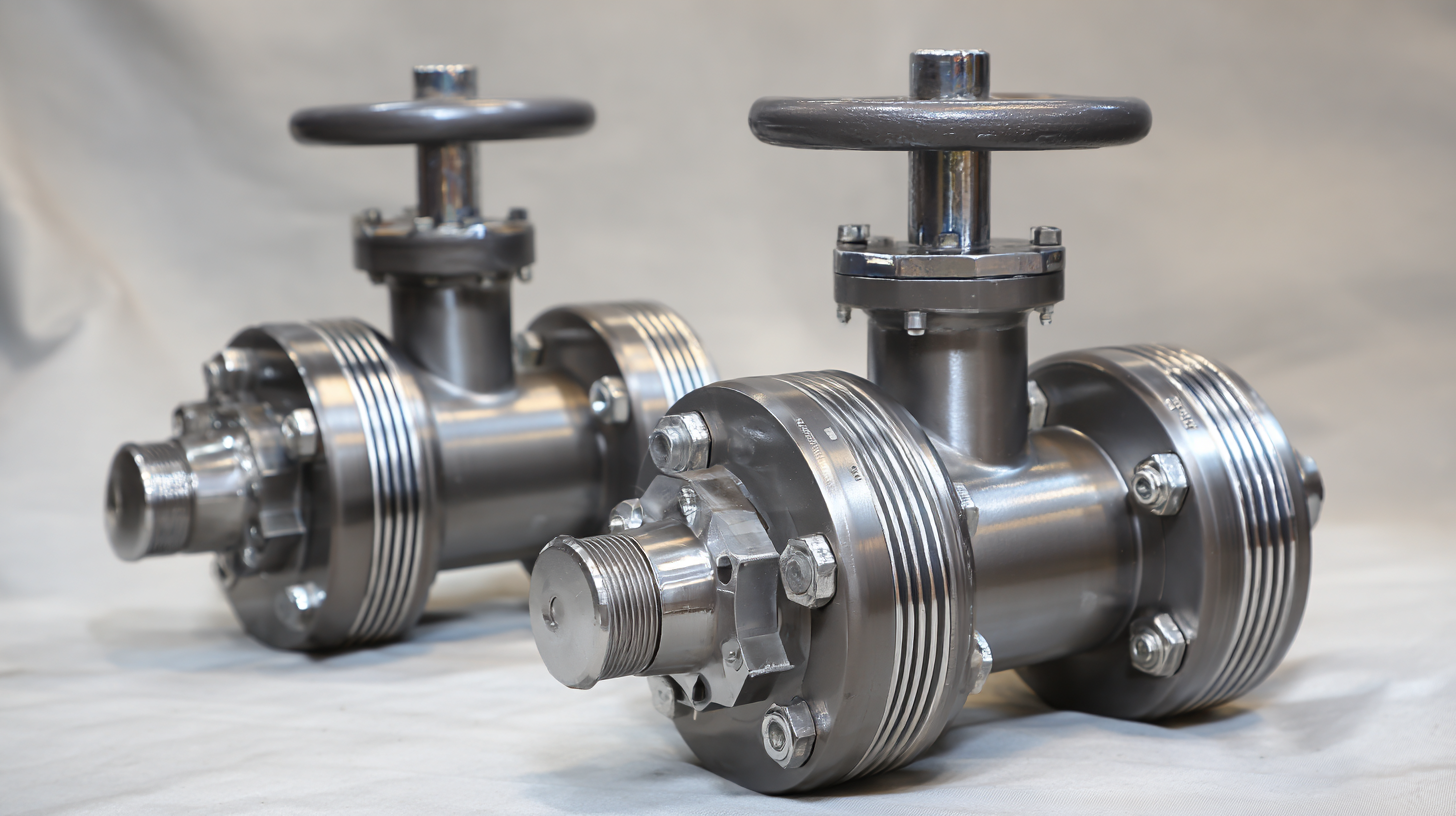

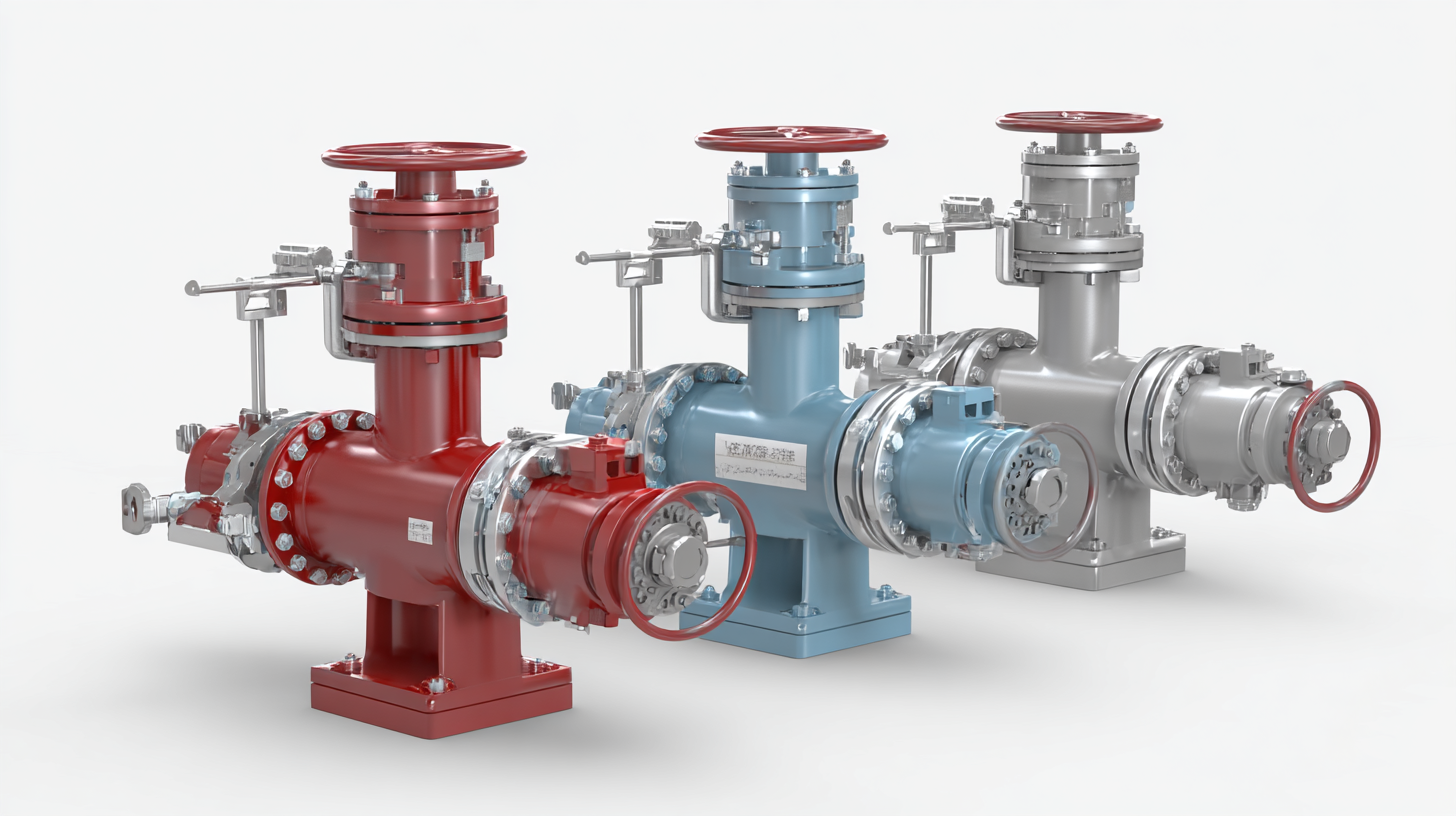

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

In industrial applications, the importance of efficient fluid control cannot be overstated, and one of the most crucial components in achieving this is the gate valve. Gate valves play a pivotal role in regulating fluid flow, ensuring that systems operate smoothly and efficiently. With numerous styles and materials available, selecting the right gate valves for specific operational needs can be a challenge.

This guide delves into the five best gate valves designed to enhance fluid control in various industrial settings. By examining their features, advantages, and ideal applications, we aim to equip you with the knowledge necessary to make informed decisions when choosing gate valves for your processes.

Whether you're involved in water distribution, chemical processing, or oil and gas operations, understanding the nuances of these essential valves will help you enhance overall efficiency and reliability in your fluid management systems.

Top Features to Consider for Gate Valves in Industrial Fluid Systems

When selecting gate valves for industrial fluid systems, several key features should be considered to ensure efficient fluid control. One of the foremost aspects is the valve’s construction material, as this can significantly impact performance under different pressures and temperatures. Utilizing materials that offer resilience against corrosion and wear is critical, particularly for applications involving aggressive fluids. Additionally, the design of the valve—such as port configuration and sealing mechanisms—plays a vital role in achieving optimal flow rates and preventing leaks.

Another important consideration is the valve’s operational capabilities under high-pressure conditions. Valves must be capable of withstanding the stress imposed by elevated pressures without compromising their integrity. Engineers should evaluate the valve sizing, pressure ratings, and actuation methods to ensure alignment with system requirements. Furthermore, regular maintenance and inspection practices are essential in high-pressure environments to mitigate the risk of failures and enhance the longevity of the gate valves in use. Proper implementation of best practices concerning valve selection and management can greatly contribute to the overall safety and efficiency of fluid control systems in industrial applications.

Comparative Analysis of Gate Valve Materials for Enhanced Durability

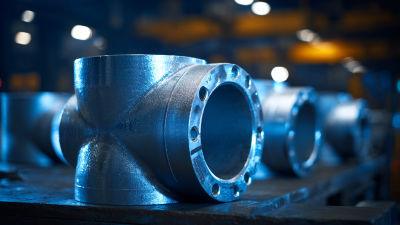

When evaluating gate valves for industrial applications, the materials used in their construction play a pivotal role in determining their durability and overall efficiency. Common materials include cast iron, stainless steel, and PVC, each offering unique advantages depending on the operational environment. For instance, cast iron valves are favored for their excellent durability and corrosion resistance in non-aggressive fluid applications, while stainless steel valves excel in environments requiring high strength and resistance to both corrosion and extreme temperatures.

Another material gaining popularity is brass, which combines good corrosion resistance with a lighter weight, making it suitable for a variety of fluid control applications. However, the choice of material must align with the specific characteristics of the fluid being transported; for example, corrosive fluids may necessitate the use of specialized alloys or coated valves. By conducting a comparative analysis of these materials, industry professionals can make informed decisions that enhance the longevity and reliability of gate valves, ultimately improving fluid control systems in their facilities.

Performance Metrics: Flow Coefficient (Cv) and Pressure Drop in Gate Valves

In industrial applications, the effectiveness of gate valves is often measured by two critical performance metrics: the flow coefficient (Cv) and pressure drop. The flow coefficient represents the valve's ability to allow fluid to pass through it, calculated based on the flow rate of water at a specific temperature and pressure drop across the valve. According to a report by the American Society of Mechanical Engineers (ASME), a typical gate valve can have a Cv range from 50 to over 400, depending on its size and design. This means that selecting a valve with the appropriate Cv is essential for optimizing fluid control in processes requiring high flow rates.

Pressure drop, on the other hand, is the resistance a fluid experiences as it passes through the valve. A significant pressure drop can lead to inefficiencies and increased energy costs in an industrial system. The Hydraulic Institute suggests that maintaining a pressure drop below 10% of the system’s total pressure is ideal for most applications. By carefully evaluating both Cv values and potential pressure drops, engineers can select gate valves that strike a balance between performance and efficiency, ultimately enhancing the operational capabilities of their fluid control systems.

Cost-Benefit Analysis of Electric vs. Manual Gate Valve Actuators

When evaluating the efficiency of gate valves in industrial applications, one notable consideration is the choice between electric and manual actuators. According to data from the International Society of Automation, electric actuators can achieve up to 30% more efficiency in operations compared to manual options, particularly in high-frequency applications. This advantage becomes crucial in environments where precision and speed are essential for maintaining fluid control, significantly reducing downtime.

However, it’s imperative for industries to conduct a cost-benefit analysis before making a switch. While electric actuators typically come with a higher upfront cost—ranging from 20% to 50% more than manual options—their potential for improved performance and reduced labor costs can lead to substantial savings over time. A report from the American Society of Mechanical Engineers suggests that companies can save as much as 15% annually following the adoption of electric actuators due to reduced maintenance and improved reliability.

Tips: When considering an actuator type, assess your specific operational needs—if frequent adjustments are required, electric actuators may be the sensible investment. Furthermore, prioritize products with a proven track record; studies show that brands with ISO certifications often offer enhanced durability and performance. Lastly, consult with manufacturers to understand the long-term total cost of ownership, which encompasses not just the initial purchase price but also maintenance and operational expenses.

Industry Standards and Certifications for Reliable Gate Valve Selection

When selecting gate valves for industrial applications, industry standards and certifications play a crucial role in ensuring reliability and efficiency. The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide frameworks for the design and manufacturing of gate valves, setting standards for performance, safety, and quality. According to a report from the International Journal of Engineering Research & Technology (IJERT), compliance with ANSI/ASME standards can reduce failure rates in industrial systems by up to 30%, highlighting the importance of adhering to recognized certifications.

In addition to ANSI and ASME standards, valves that have received certifications from the American Petroleum Institute (API) are often preferred in sectors such as oil and gas. API standards, particularly API 6D, ensure that valves are rigorously tested for pressure and leakage, guaranteeing their suitability for high-demand applications. The Global Market Insights report shows that the integration of certified gate valves can improve operational efficiency by as much as 25% in fluid control systems. Therefore, when selecting gate valves, it is essential for engineers and procurement managers to prioritize industry certifications to achieve superior performance and reliability.

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

| Valve Size | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications | Certifications |

|---|---|---|---|---|---|

| 2 inches | Carbon Steel | 150 | -20 to 300 | Water, Oil, Gas | API 6D, ANSI |

| 4 inches | Stainless Steel | 300 | -50 to 600 | Chemical Processing | ASTM, ASME |

| 6 inches | Ductile Iron | 150 | -20 to 250 | Water Treatment | AWWA, NSF |

| 8 inches | Bronze | 300 | 0 to 400 | Marine Applications | CE, ISO |

| 10 inches | PVC | 150 | -40 to 140 | Irrigation | UL, CSA |

Related Posts

-

How to Choose the Right Flanges and Fittings for Your Project

-

How to Choose the Right Flange Valves for Your Industrial Needs

-

The Role of Butterfly Valves in Modern Industry: A Comprehensive Overview

-

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights

-

7 Best Butterfly Valves for Enhanced Industrial Performance in 2024

-

A Comprehensive Guide to Choosing the Right Weld Fittings for Your Projects