Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Why Choose Sharpe Ball Valves for Your Industrial Applications and Needs

In the ever-evolving landscape of industrial applications, the choice of valves plays a pivotal role in ensuring efficiency and reliability. Among the myriad options available, Sharpe Ball Valves stand out for their superior performance and durability. Industry expert Dr. Emily Johnson, a renowned valve specialist, asserts, "Choosing the right valve can make all the difference in operational efficiency, and Sharpe Ball Valves excel in providing that reliability." This statement encapsulates the essence of why these ball valves have become a preferred choice for many applications.

Sharpe Ball Valves are designed to facilitate seamless flow control, making them invaluable in various industrial processes. Their robust construction and corrosion-resistant materials ensure they can withstand the rigors of demanding environments. Whether used in chemical processing, oil and gas, or water treatment, these valves deliver unmatched performance and longevity.

As we delve deeper into the benefits and applications of Sharpe Ball Valves, it becomes evident that their design, functionality, and reliability are key factors driving their adoption across multiple industries. By understanding what makes these valves a top choice, industrial operators can make informed decisions that enhance productivity and safety in their operations.

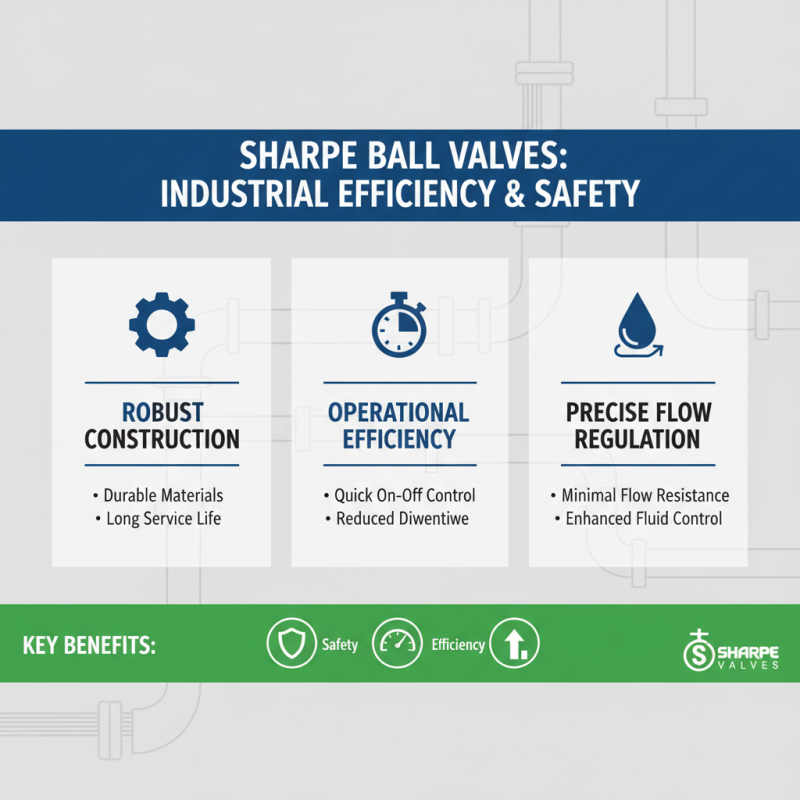

Advantages of Sharpe Ball Valves in Industrial Settings

When it comes to industrial applications, the choice of valves significantly impacts efficiency and safety. Sharpe ball valves stand out due to their robust construction and operational efficiency. These valves feature a simple yet effective design that allows for quick on-off control, significantly reducing downtime in various processes. Their spherical closure element ensures minimal flow resistance and enhances fluid control, making them ideal for applications requiring precise regulation of flow.

Tips for ensuring optimal performance with ball valves include regular maintenance checks to prevent wear and tear. It’s essential to inspect the seals and seats periodically, as any degradation can lead to leaks, compromising system integrity. Additionally, always ensure that the valve is fully closed or fully opened during operation to prevent unnecessary strain and extend the lifespan of the valve.

Moreover, the corrosion-resistant materials used in Sharpe ball valves make them suitable for a wide range of chemicals and conditions, contributing to long-term reliability. In extreme environments, opting for valves with enhanced protective coatings can further ensure performance stability. Always consider the specific needs of your application when selecting valve materials to maximize efficiency and durability.

Key Features of Sharpe Ball Valves for Improved Performance

When evaluating ball valves for industrial applications, several key features make them an optimal choice for enhanced performance. First and foremost, the design of ball valves allows for quick and reliable shut-off, minimizing the risk of leaks and ensuring that systems operate safely and efficiently. The spherical disc provides a clear path for fluid flow when open and an airtight seal when closed, significantly reducing friction loss and improving overall flow characteristics.

Additionally, the materials used in the construction of these valves play a crucial role in their durability and resistance to corrosion. Often crafted from high-quality metals and polymers, they can withstand harsh environments and extreme temperatures, making them suitable for a variety of industrial applications. This resilience not only extends the lifespan of the valves but also reduces maintenance costs and downtime, contributing to increased productivity in industrial settings.

Finally, the compact design of ball valves enables easy installation and integration within existing piping systems. This flexibility is particularly beneficial in spaces where size constraints are a concern. Moreover, their straightforward operation contributes to ease of use, allowing for efficient control over fluid flow. By understanding these features, industries can make informed decisions that enhance process reliability and operational excellence.

Why Choose Sharpe Ball Valves for Your Industrial Applications and Needs - Key Features of Sharpe Ball Valves for Improved Performance

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Durability | Designed for long-term use under harsh conditions | Reduced maintenance costs and downtime | Oil & Gas, Water Treatment |

| Flow Control | Optimized for high flow rates | Improved efficiency in operations | Chemical Processing, HVAC |

| Versatility | Suitable for various media, including corrosive fluids | Adaptable to numerous industrial needs | Pharmaceutical, Food & Beverage |

| Leak-Proof Design | Advanced sealing technology for zero leakage | Increased safety and reliability | Water Supply, Waste Management |

| Ease of Maintenance | Simple disassembly for quick servicing | Lower operational costs | Mining, Power Generation |

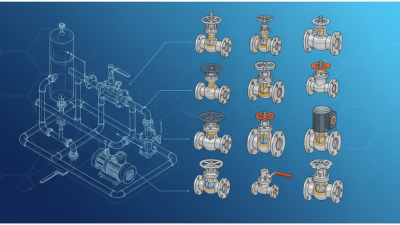

Comparing Sharpe Ball Valves with Other Valve Types

When evaluating different valve types for industrial applications, Sharpe ball valves stand out due to their unique operational advantages. Compared to gate valves, which can suffer from slow operation and high pressure loss, ball valves provide a quick shut-off feature and significantly lower resistance to flow. This efficiency is crucial for processes requiring rapid response times, making ball valves a preferred choice for industries where operational speed is vital.

In contrast to globe valves, which excel in throttle control but often lead to pressure drops due to their design, Sharpe ball valves maintain a consistent flow with minimal drop in pressure. Their streamlined design allows for unobstructed flow paths, enhancing their suitability for high-pressure applications. Additionally, unlike butterfly valves that may offer quick results but can leak over time, ball valves ensure a tight seal and durability under various temperature and pressure conditions, thereby reducing maintenance needs and extending service life.

Ultimately, the choice of valve type has significant implications for system performance and efficiency. By understanding these distinctions, industries can make informed decisions that align with their operational needs and ensure optimal performance from their valve systems.

Applications of Sharpe Ball Valves in Various Industries

Sharpe ball valves are widely utilized across a variety of industries due to their reliability and efficiency in fluid control applications. In the oil and gas sector, these valves play a crucial role in managing the flow of hydrocarbons, providing effective shut-off capabilities that enhance safety and operational efficiency. Their robust design allows them to withstand high pressures and temperatures, making them ideal for extraction and refining processes. Additionally, the ability to operate smoothly under varying conditions ensures minimal downtime and maintenance, which is vital for productivity in this industry.

In the chemical processing industry, Sharpe ball valves are essential for maintaining controlled environments during the transportation of corrosive and hazardous materials. Their tight sealing mechanisms prevent leaks, safeguarding both personnel and equipment while maintaining process integrity. Furthermore, with the compatibility of various materials, these valves can be utilized in a range of applications, from simple on/off control to more complex multi-port configurations. This versatility extends to the water treatment and food processing sectors, where reliable performance in handling various fluids is critical for ensuring compliance with health and safety regulations.

Applications of Sharpe Ball Valves in Various Industries

Maintenance and Durability of Sharpe Ball Valves for Long-Term Use

When it comes to industrial applications, the choice of ball valves plays a significant role in ensuring operational efficiency and reliability. One of the key advantages of certain high-quality ball valves is their low maintenance and robust durability, which are essential for long-term use in demanding environments. Properly designed ball valves can withstand extreme temperatures, pressures, and corrosive substances, thereby minimizing the risks of leaks and failures that can disrupt operations and lead to costly downtime.

Regular maintenance is essential for extending the lifespan of any valve, but certain types of ball valves require less frequent servicing due to their self-cleaning action and simple design. This feature can significantly reduce maintenance costs and labor efforts, allowing personnel to focus on other critical tasks. Furthermore, the materials used in the construction of these valves often include high-grade metals and coatings that provide excellent resistance against wear and tear, ensuring reliable performance over time.

With such attributes, industries can confidently operate with reduced worries about valve failure while enjoying the benefits of seamless flow control.

Related Posts

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Discover the Benefits of Using Sharpe Ball Valves for Your Industrial Applications

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

Top 10 Ball Valves for Optimal Performance and Reliability in Your Projects