Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

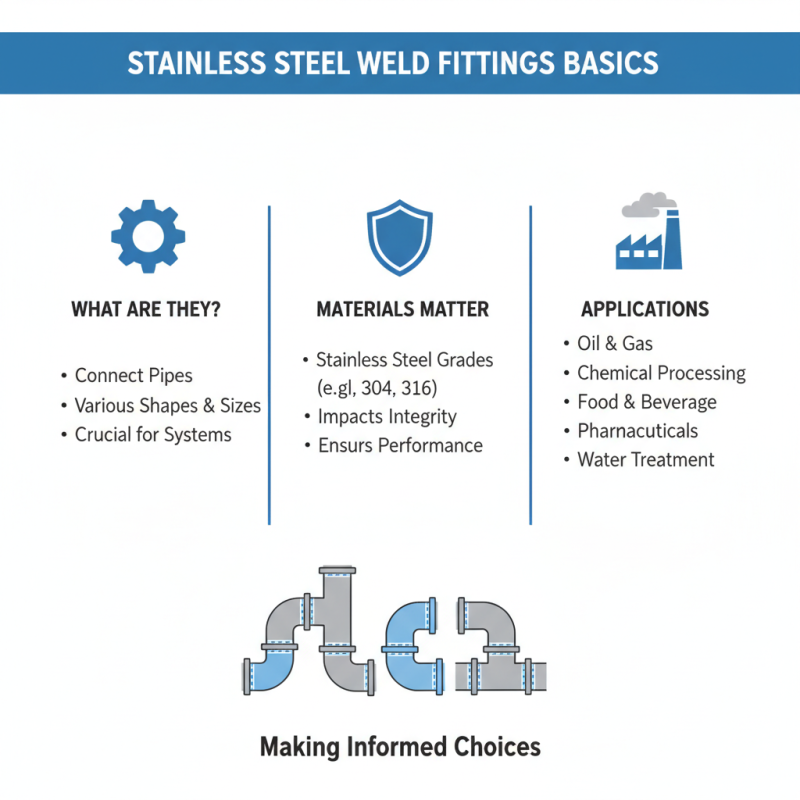

How to Choose the Best Stainless Steel Weld Fittings?

Choosing the best stainless steel weld fittings is a crucial process in various industries. According to John Smith, an expert in industrial piping systems, "Quality stainless steel weld fittings ensure durability and safety." The right choice can impact overall project success.

When selecting stainless steel weld fittings, consider material grade. Different grades offer varied corrosion resistance and strength. Detail matters. A small oversight can lead to costly repairs later. Not all options are equal.

Many don’t realize the importance of proper dimensions. Ill-fitting fittings can cause leaks. Taking precise measurements can save time and frustration. Remember, investing time in choosing quality fittings is essential for long-term performance.

Understanding the Basics of Stainless Steel Weld Fittings

Stainless steel weld fittings are crucial in many applications. Understanding their basics helps you make informed choices. These fittings come in various shapes, sizes, and grades. Typically, they are used to connect pipes in a system. The materials used impact the overall integrity and performance.

When selecting a fitting, consider its compatibility with your pipes. Different grades of stainless steel have unique properties. Using the wrong grade can lead to corrosion or failure. Pay attention to specifications and certifications. This attention to detail can save time and money in the long run.

Tips: Inspect the welding process. Poor welding can weaken the joint. Look for visual signs of defects. Also, evaluate the service conditions. This includes temperature and pressure extremes. Ensure the fitting can handle the environment.

Sometimes, choices may not be clear. Reflect on alternatives, even if they seem less favorable. Research all available options. This can lead to better outcomes in your projects. Always weigh the pros and cons of each fitting type before making a decision.

Identifying Different Types of Stainless Steel Weld Fittings

When choosing stainless steel weld fittings, understanding the different types is essential. Weld fittings come in various shapes and sizes, designed for specific applications. Common types include elbows, tees, reducers, and nipples. Each has unique features suited for specific purposes.

Experts note that the grade of stainless steel also matters. For instance, 304 and 316 grades are popular choices. According to industry reports, 316 stainless steel offers better corrosion resistance than 304. This makes it suitable for marine applications. In contrast, 304 is often used in less demanding environments.

Tip: Always assess your project needs. Consider the environment where the fittings will be used. If corrosive substances are involved, opt for higher grade stainless steel for durability.

It’s important to remember that not all fittings are created equal. Some may not conform to industry standards, leading to failures. Research manufacturers thoroughly. Look for certifications and test reports before making a decision.

Tip: Check for compatibility with existing piping systems. A fitting that doesn’t match can lead to leaks or costly repairs.

How to Choose the Best Stainless Steel Weld Fittings?

This chart illustrates the different types of stainless steel weld fittings and their percentage usage in various applications.

Evaluating Quality and Standards for Stainless Steel Weld Fittings

When evaluating quality and standards for stainless steel weld fittings, several key aspects must be considered. The composition of the stainless steel, often indicated by grades like 304 and 316, is crucial. Grade 304 offers decent corrosion resistance, but for harsher environments, grade 316 is preferred, known for its superior durability in saltwater applications. Reports from industry bodies suggest that 304 and 316 grades account for 85% of the market share for fittings due to their versatility.

Fabrication standards are equally important. Looking for compliance with ASTM A403 or ASME B16.9 can ensure product integrity. Many manufacturers struggle to meet these standards consistently. A study by the American Society for Testing and Materials highlighted that 30% of the tested fittings did not meet the required specifications. This raises concerns about quality control in the industry. Buyers should consider obtaining certifications or third-party inspections before making purchases.

Additionally, welding techniques play a significant role in the performance of these fittings. Proper methods, like TIG welding, can enhance strength and reduce defects. Yet, not all manufacturers maintain high welding standards. Reports show that poorly welded joints can account for a 40% failure rate in field applications. This highlights the need for thorough research before investing in stainless steel weld fittings.

How to Choose the Best Stainless Steel Weld Fittings?

| Type of Fitting | Material Grade | Size Range (inches) | Pressure Rating (PSI) | Standards Compliance |

|---|---|---|---|---|

| Elbow | 316L | ½ - 6 | 1500 | ASTM A312 |

| Tee | 304 | ½ - 8 | 1000 | ASME B16.9 |

| Cross | 316 | 1 - 4 | 600 | ANSI B16.28 |

| Reducer | 321 | 2 - 8 | 800 | ISO 1127 |

Factors to Consider When Choosing Weld Fittings

When selecting stainless steel weld fittings, several factors should come into play. The most crucial is the application. Consider the operating environment. Some applications demand resistance to corrosion, while others require high strength. For example, fittings used in marine settings need superior corrosion resistance due to exposure to saltwater and air.

Another essential factor is the fitting size. Accurate measurements are vital. Mis-sizing can lead to leaks or structural failures. According to industry reports, nearly 30% of fitting failures arise from improper sizing. Additionally, the grade of stainless steel matters. Grades like 304 and 316 each serve different purposes. 316 is preferred for environmental resistance, while 304 is often less expensive.

Tips: Always check for compliance with industry standards. Look for certifications to ensure quality. Don't overlook the need for proper welding techniques, as poor welds can compromise fitting integrity. It’s also wise to consult with professionals if uncertain about specifications. Investing in quality fittings is essential, but cheap fittings can lead to costly repairs later on. Make sure the choices align with long-term operational needs, reflecting a commitment to durability.

Assessing the Importance of Compatibility and Sizing

Choosing weld fittings requires careful consideration of compatibility and sizing. Many industries rely on precise measurements for effective installations. In fact, a survey by the American Society of Mechanical Engineers found that improper sizing accounts for over 30% of failures in piping systems. This statistic highlights the critical nature of matching fittings with the appropriate piping sizes.

Incompatible fittings can lead to leaks or structural failures. For example, in industries like oil and gas, even a minor deviation in size can result in disastrous outcomes. It’s essential to check the nominal pipe size and schedule. The difference of a few millimeters can be significant, affecting flow rates and pressure. Data from the International Journal of Pressure Vessels and Piping suggests that nearly 20% of maintenance issues trace back to incorrect fittings.

Choosing the wrong material can also lead to miscommunication between components. Stainless steel offers great corrosion resistance, but not all stainless steel grades are created equal. Incompatible grades may not withstand specific environments. Addressing these factors requires a comprehensive understanding of both the application and environmental conditions. Meanwhile, staying updated with industry standards helps in making informed decisions. Ignoring these aspects can be a costly oversight.

Related Posts

-

Why Stainless Steel Weld Fittings Are Essential for Modern Industrial Applications

-

The Future of Steel and Fittings Innovation Trends Data and Best Practices

-

Maximizing Efficiency and Longevity with Titan Valves in Industrial Applications

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

How to Choose the Right Flange Valves for Your Plumbing System

-

Understanding Flow Valves: How They Optimize Fluid Control with 30% Efficiency Gains in Industry