Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

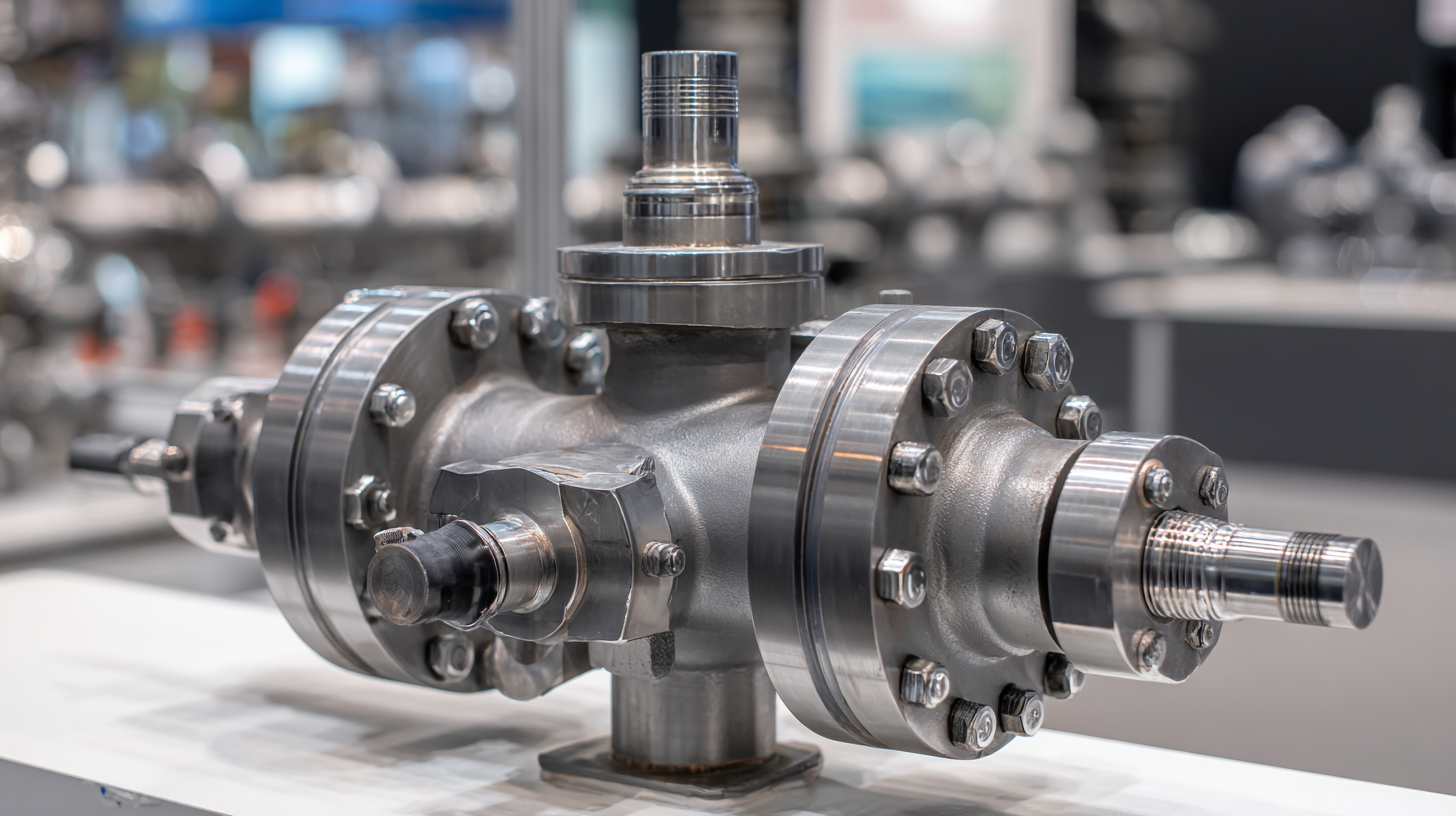

How to Choose the Right Needle Valve for Global Industrial Applications

In the realm of global industrial applications, the selection of the appropriate needle valves can significantly influence operational efficiency and system integrity. According to a recent report by MarketsandMarkets, the global needle valve market is projected to reach $1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.5% from 2020. This growth underscores the critical role needle valves play in various industries, including oil and gas, chemical processing, and pharmaceuticals, where precise flow control is paramount. When navigating the complexities of valve selection, it is essential to consider factors such as material compatibility, pressure rating, and application-specific requirements. As industries demand more reliable and efficient systems, understanding how to choose the right needle valve becomes an imperative for engineers and decision-makers alike.

Factors to Consider When Selecting Needle Valves for Industrial Systems

When selecting needle valves for industrial systems, it’s crucial to consider several key factors to ensure optimal performance and efficiency. First, the fluid type plays a significant role; chemical compatibility must be assessed to prevent corrosion or degradation. For example, aggressive chemicals may require valves made from specialized alloys or plastics, while more inert substances could be suited to standard materials. Additionally, understanding the flow characteristics of the fluid can help in choosing the right needle valve design, as this impacts the valve's ability to regulate flow accurately.

Another important consideration is the pressure and temperature range in which the needle valve will operate. Valves must be rated for the maximum operating conditions to maintain safety and reliability. Choosing the correct size is equally essential; a valve that is too large may lead to poor control of flow, while one that is too small can restrict performance. Furthermore, the installation environment, such as cleanliness and accessibility, should also inform your selection, ensuring the valve can be easily maintained and replaced as needed. Taking these factors into account will significantly enhance the effectiveness of your industrial systems.

Understanding Different Needle Valve Types for Global Applications

When selecting the right needle valve for global industrial applications, understanding the different types available is crucial. Needle valves are predominantly used for precise flow control in various industries, and their design can significantly vary based on the application needs. For instance, a conventional needle valve is suitable for applications that require moderate flow precision, while a high-pressure needle valve is engineered to handle rigorous environments, offering enhanced durability and performance.

Furthermore, considering recent advancements in industrial technology, such as the rising trend in automated systems, one must align the choice of needle valve with the operational requirements. Enhanced features, like those seen in advanced purging systems and automated controls, can improve efficiency in fluid handling processes. Industries transitioning to cleaner energy solutions might also benefit from specialized needle valves designed to support hydrogen applications, highlighting the importance of selecting a valve that meets current technological demands while addressing future energy trends.

Key Performance Metrics to Evaluate in Needle Valve Selection

When selecting the right needle valve for global industrial applications, several key performance metrics must be evaluated to ensure optimal operation and reliability. One primary consideration is flow coefficient (Cv), which measures the valve's capacity to allow fluid flow. According to a report by the Valve Manufacturers Association (VMA), optimal Cv ratings can significantly impact energy efficiency and operational costs, with valves operating at higher Cv values achieving up to 20% lower power consumption in certain applications.

Another critical metric is pressure drop, particularly in applications involving high-pressure systems. A study published by the American Society of Mechanical Engineers (ASME) highlights that selecting a needle valve with an appropriate pressure drop can prevent system overloading and reduce the risk of failure, contributing to enhanced safety and longevity of equipment. Additionally, materials of construction play a vital role in performance; for instance, using corrosion-resistant materials can extend the lifespan of needle valves in harsh environments, reducing maintenance costs by up to 30%, as indicated in a comprehensive industry analysis by the International Journal of Fluid Mechanics.

It is essential that engineers and procurement teams prioritize these metrics alongside factors such as size and end connections to make informed decisions that align with specific application demands.

Material Compatibility: Ensuring Longevity in Harsh Environments

When selecting the right needle valve for industrial applications, material compatibility plays a pivotal role, especially in harsh environments. The chosen materials must withstand not only the mechanical stresses but also the corrosive elements typically found in these settings. Recent advancements in materials science, such as non-flammable fluorinated gel polymers, provide innovative alternatives that ensure the longevity and reliability of components under extreme conditions. These materials demonstrate exceptional properties that can enhance the durability of needle valves, making them suitable for applications where traditional materials may fail.

Moreover, the development of fibre-reinforced polymers has opened new avenues for creating valves that are lightweight yet resistant to corrosion and environmental stressors. This is particularly relevant in industries where equipment is subjected to varying temperatures and moisture levels. By leveraging these advanced materials, engineers can design needle valves that maintain optimal performance, circumventing the challenges posed by traditional materials that may degrade over time. As industries increasingly adopt sustainable practices, choosing the right materials not only helps in achieving operational efficiency but also aligns with environmental goals, paving the way for a more resilient industrial future.

Cost-Effectiveness: Balancing Quality and Budget in Needle Valve Choices

When selecting a needle valve for global industrial applications, cost-effectiveness is a critical factor that requires careful consideration. Balancing quality and budget ensures that businesses can achieve optimal performance without overspending. High-quality needle valves often come at a premium, yet they offer benefits such as durability, reliability, and a lower total cost of ownership over time. Investing in well-manufactured valves can reduce downtime and maintenance costs, ultimately leading to significant savings.

Moreover, it's essential to analyze the long-term implications of purchasing decisions. Cheaper alternatives may appear appealing initially, but they may not withstand harsh operating conditions, leading to frequent replacements. Assessing the total lifecycle cost—factoring in installation, maintenance, and operational efficiency—can provide a clearer picture of how to best allocate resources. By prioritizing quality while remaining budget-conscious, industries can select needle valves that not only meet their immediate needs but also contribute to overall operational efficiency and sustainability.

How to Choose the Right Needle Valve for Global Industrial Applications - Cost-Effectiveness: Balancing Quality and Budget in Needle Valve Choices

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Cost ($) |

|---|---|---|---|---|

| Standard Needle Valve | Stainless Steel 316 | 6000 | -40 to 200 | 25 |

| High Pressure Needle Valve | Carbon Steel | 10000 | -20 to 300 | 40 |

| Low Flow Needle Valve | Brass | 1500 | 0 to 150 | 15 |

| High Temperature Needle Valve | Monel | 3000 | -40 to 800 | 60 |

Related Posts

-

How to Choose the Right Stainless Fittings for Your Industrial Needs

-

Exploring Alternative Weld Fittings: Innovative Solutions for Global Procurement Needs

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends

-

Top Strategies for Sourcing High Quality Steel Fittings

-

A Comprehensive Guide to Choosing the Right Weld Fittings for Your Projects