Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

How to Choose the Right Needle Valves for Your Applications

Needle valves play a crucial role in various industrial applications. They are designed to control the flow of liquids and gases efficiently. According to a recent industry report, the global needle valve market is expected to grow at a CAGR of 4.5% between 2021 and 2026. This increasing demand emphasizes the importance of selecting the right needle valves for specific applications.

The choice of needle valves can significantly impact system performance. Inaccurate selection may lead to pressure drops or inefficient flow control. Studies indicate that improper valve sizing can reduce overall system efficiency by up to 15%. It's essential to consider factors such as material compatibility, operating pressure, and temperature when making a selection.

For instance, stainless steel needle valves are often preferred in corrosive environments. However, they may not be ideal for all situations. Mistakes in selection can lead to costly downtime or system failures. Careful consideration of these factors can lead to improved performance and longevity of the equipment. Proper knowledge of needle valves is vital for engineers and operational staff alike.

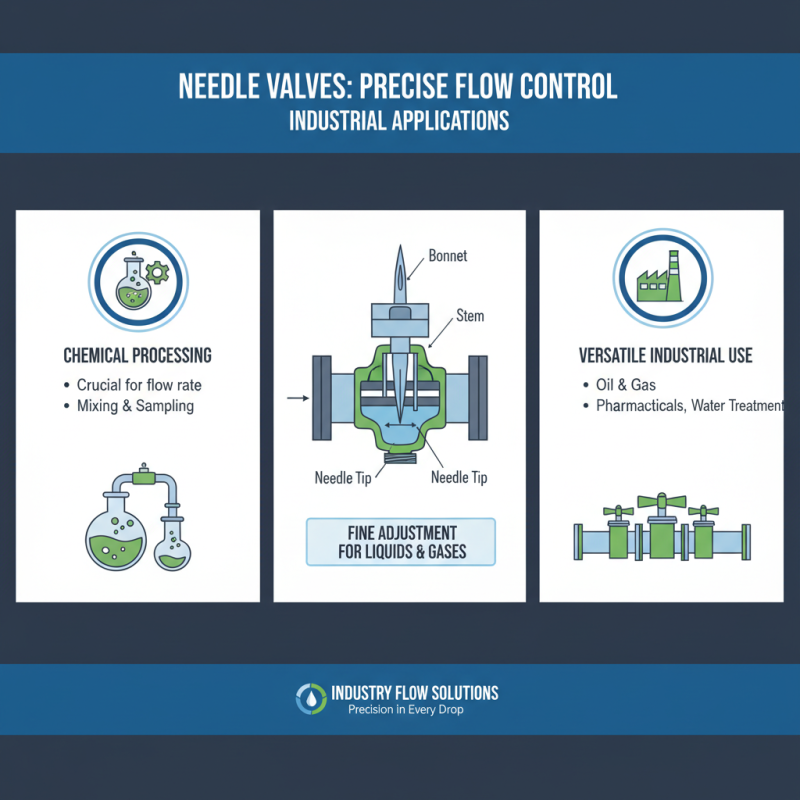

Understanding Needle Valve Functions in Fluid Control Applications

Needle valves play a crucial role in fluid control applications. They offer precise regulation of flow, making them ideal for various industries. These valves feature a slender, tapered design that allows for small adjustments in fluid flow. Reports indicate that the global needle valve market is expected to grow by 5% annually, highlighting their growing importance.

In high-stakes environments, accuracy is vital. A small miscalculation could lead to significant issues in a system. For instance, in chemical processing, a needle valve's ability to manage flow rates can prevent hazardous situations. Some reports suggest that improper flow control contributes to nearly 30% of operational failures in plants. This data underscores the need for careful selection and implementation of needle valves.

However, choosing the right needle valve isn’t always straightforward. Factors like fluid type, pressure, and temperature must be considered. Inappropriate choices can lead to inefficiencies and safety hazards. It’s important to analyze the specific requirements of your application. Testing various options can provide insights. Reflecting on previous experiences can help in making informed decisions.

Key Technical Specifications to Consider When Selecting Needle Valves

When selecting needle valves, understanding technical specifications is crucial. Key factors include material compatibility, flow rate, and pressure rating. Choose materials based on the medium you will handle. For example, corrosive fluids may need special alloys. Make sure the valve can withstand the pressures of your system. An inadequate rating can lead to failure.

Flow rate is another important aspect. This can affect efficiency. If it’s too low, your system may not work effectively. If it’s too high, it may cause noise or damage. It’s essential to match the valve’s flow characteristics with your needs. Testing can reveal some trial and error.

Don’t overlook the product's size and connection type. Valves come in various sizes and thread types. Check the dimensions carefully. A mismatch could complicate installation. Take time to consider each specification, rather than rushing the decision. Sometimes, an overlooked detail can lead to costly mistakes.

How to Choose the Right Needle Valves for Your Applications - Key Technical Specifications

| Specification | Description | Importance |

|---|---|---|

| Body Material | Common materials include brass, stainless steel, and PVC. | Choice impacts corrosion resistance and pressure ratings. |

| Connection Type | Options include threaded, flanged, or welded connections. | Affects installation compatibility and leak prevention. |

| Pressure Rating | Refers to the maximum allowed pressure for operation. | Critical for safe operation and preventing failures. |

| Temperature Range | Operating temperature limits for the valve material. | Ensures functionality in varying environmental conditions. |

| Size | Available in various dimensions (e.g., 1/4", 1/2"). | Impacts flow rate and compatibility with piping systems. |

| Seal Type | Includes options like PTFE, rubber, or metal seals. | Affects sealing performance and chemical compatibility. |

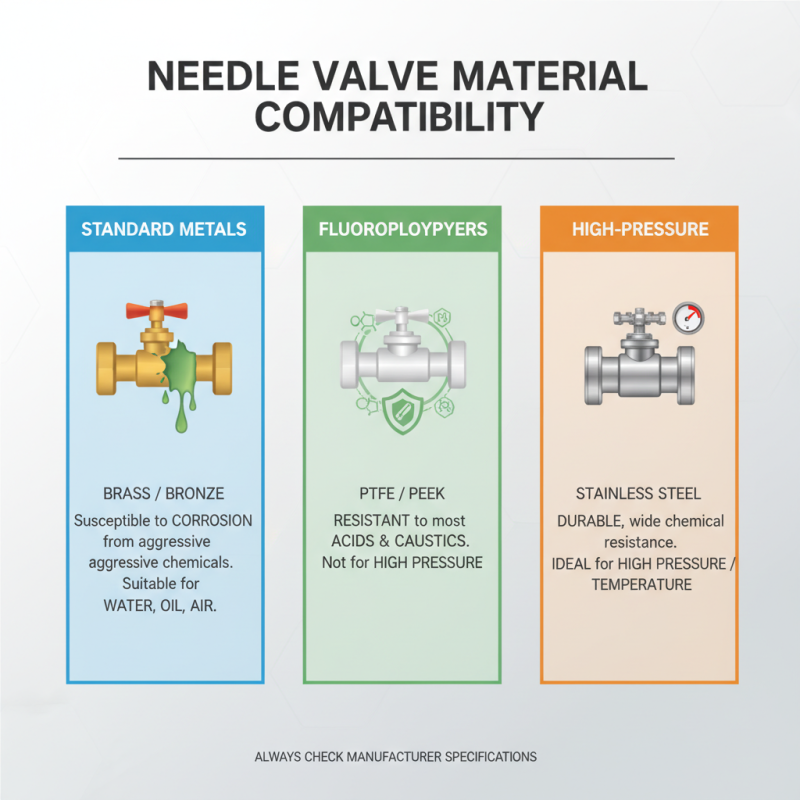

Material Compatibility: Choosing Needle Valves for Different Media

Choosing the right needle valves involves understanding material compatibility. Different media interact uniquely with valve materials. For example, corrosive chemicals can severely damage standard brass or bronze valves. Fluoropolymers are effective against many aggressive substances. However, these materials may not be suitable for high-pressure applications.

Take the time to evaluate the media. Consider temperature and pressure conditions. Water, oil, and gas should all be assessed differently. If using water, ensure the valve is resistant to corrosion. Some users overlook this critical aspect, leading to premature failure.

Don’t forget about the environment. Harsh conditions like extreme temperatures require specialized materials. A poorly chosen valve can result in leaks or failures. Such issues not only waste resources but can also lead to safety hazards. Reflect on the long-term implications of your choices. A thoughtful selection process pays off in durability and reliability over time.

Pressure and Temperature Ratings: Ensuring Valve Performance and Safety

When selecting needle valves, understanding the pressure and temperature ratings is vital. These ratings determine how well a valve can perform under specific conditions. Failing to consider them can lead to leaks or valve failure. It's crucial to know the operating environment.

Tips: Always check the manufacturer's specifications for the maximum pressure and temperature. This ensures safety and reliability. Different materials have varying resistance to temperature and pressure. For instance, stainless steel may withstand higher temperatures than plastic.

Consider the application's needs carefully. Are you dealing with corrosive fluids? Or perhaps high pressures? Each scenario requires a different approach. Choosing the wrong valve can be detrimental. Assessing your requirements beforehand can save time and resources. Remember, not all valves are created equal. Every detail matters in valve selection.

Pressure and Temperature Ratings of Needle Valves

Common Applications of Needle Valves in Industrial Settings

Needle valves are widely used in various industrial applications. They offer precise flow control in liquids and gases. One common application is in chemical processing. In this sector, controlling the flow rate is crucial. The fine adjustments of needle valves make them suitable for mixing and sampling.

Another significant application is in water treatment facilities. Needle valves regulate water flow during different treatment stages. The ability to make small adjustments is vital for maximizing efficiency. However, selecting the right valve can be challenging. Understanding the medium's properties is essential. For instance, corrosive fluids may require specific materials for durability.

Additionally, needle valves find use in HVAC systems. They help control refrigerant flow in cooling systems. Improper selection can lead to inefficiencies. Users often overlook factors like temperature and pressure ratings. These parameters can significantly impact performance. It's important to reflect on these aspects before making a decision. The right needle valve can enhance system reliability and longevity.

Related Posts

-

10 Essential Tips for Choosing the Right Needle Valves for Your Projects

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

Understanding Needle Valves and Their Key Role in Fluid Control Systems

-

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

-

The Essential Guide to Choosing the Right Stainless Flanges for Your Projects

-

How to Choose the Right Flange Gasket for Your Project