Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

What are Crane Valves and How Do They Work?

Crane valves play a vital role in various industries. They are essential components used to control fluid flow within pipelines. Understanding how crane valves work can improve system efficiency and safety.

These valves are designed with intricate mechanisms. Their operation relies on precise movements, often involving rotating or sliding parts. When properly used, crane valves can prevent leaks and ensure smooth operation. However, improper installation can lead to significant issues.

Maintenance is crucial for crane valves. Regular checks can help identify wear and tear. Neglecting regular service may result in costly repairs later on. It's important to understand their functionality to avoid common pitfalls in operation.

What Are Crane Valves: An Overview of Their Design and Function

Crane valves are essential components in many piping systems. They control the flow of liquids and gases. Their design is critical for functionality. A typical crane valve features a body, a disc, and a mechanism for operation. This mechanism can be manual or automated.

The valve's disc moves to open or close the passage. Depending on the position, it regulates flow. When open, fluids can pass through freely. When closed, the flow is halted. Proper installation is vital to prevent leaks. Common materials for these valves include metal and plastic, which impact durability and performance.

Crane valves can face challenges. Sometimes, they may not seal tightly, causing leaks. Corrosion can occur over time, affecting efficiency. Regular maintenance and inspections are necessary. This ensures they operate smoothly and last longer. Users must remain vigilant about these issues.

Crane Valves Performance Data

This chart illustrates the performance of various types of crane valves based on their flow rates and pressure drops. The data represents the efficiency of different valve designs in industrial applications.

Key Components of Crane Valves and Their Roles in Operation

Crane valves are essential for controlling fluid flow in various systems. They consist of multiple key components that ensure effective operation. The main body of the valve is robust, usually made from metal or high-grade plastic. This body houses the internal mechanisms that manage flow direction and volume.

The actuator is another critical part. It controls how the valve opens or closes. Operators need to ensure this component is functioning well. If the actuator fails, the valve becomes unreliable. Additional parts include the seals and gaskets. These elements prevent leaks and maintain pressure. The quality of seals is vital for efficiency. Poor seals lead to unwanted loss of fluids, which can be both costly and wasteful.

Each part has its role, but they must work together seamlessly. Maintenance is often overlooked. Regular checks can prevent bigger issues down the line. It’s easy to take these components for granted. However, being mindful of their function can improve overall system performance. A small change in one part can affect the entire operation. This interconnectedness requires constant vigilance and proactive care.

The Working Mechanism of Crane Valves: A Step-by-Step Explanation

Crane valves play a crucial role in various industrial applications. Their primary function is to regulate the flow of liquids and gases. Understanding how these valves operate is essential for effective system management.

The working mechanism of crane valves is relatively straightforward. The valve consists of a movable part called the disc, which can be rotated or lifted. This action opens or closes the flow path. When the disc is lifted, fluid can pass through. When it closes, flow is halted. The design ensures a seal that minimizes leaks.

Tips: Regularly check for wear and tear. A damaged valve may lead to inefficiencies. Consider lubrication to ensure smooth operation.

The mechanism relies heavily on precision. An improperly installed valve can disrupt the entire system. Users should regularly inspect their crane valves for alignment. Over time, sediment buildup can hinder function. It requires diligence to maintain optimal performance.

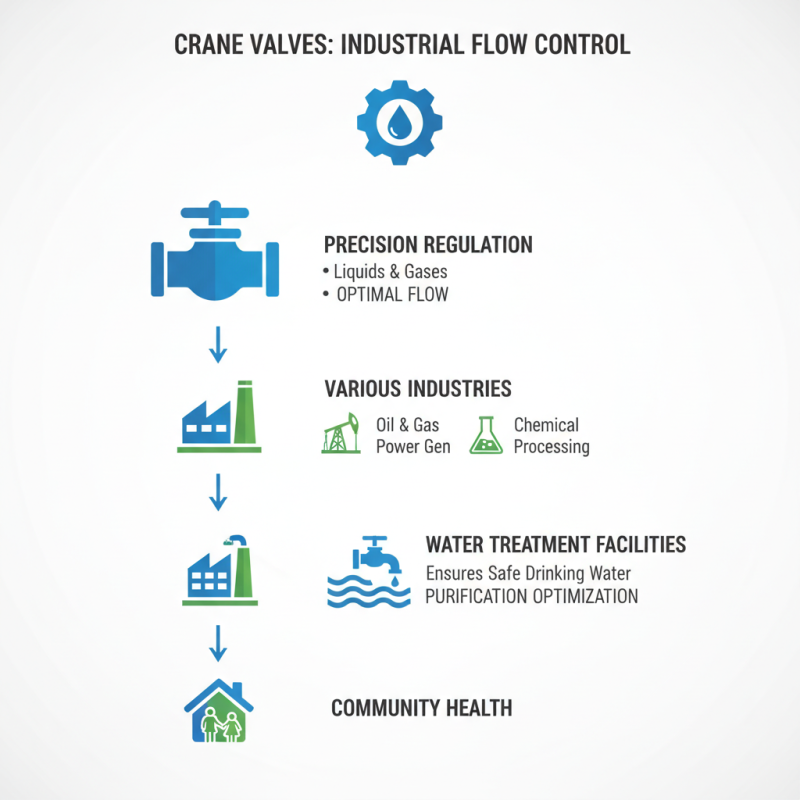

Applications of Crane Valves in Various Industries

Crane valves play a pivotal role in various industries. They regulate the flow of liquids and gases with precision. One common application is in water treatment facilities. Here, crane valves manage flow rates for optimal purification. This ensures safe drinking water for communities.

Another significant application is in the oil and gas industry. Crane valves control pressures in pipelines. This is crucial for preventing leaks and accidents. They are designed to withstand extreme conditions. However, wear and tear can be an issue. Regular inspections are needed.

Tip: Always check for corrosion. It can compromise valve integrity. Additionally, consider environmental factors like temperature changes. These can affect valve performance. Addressing potential issues early can save time and costs later. Be proactive in maintenance and repairs.

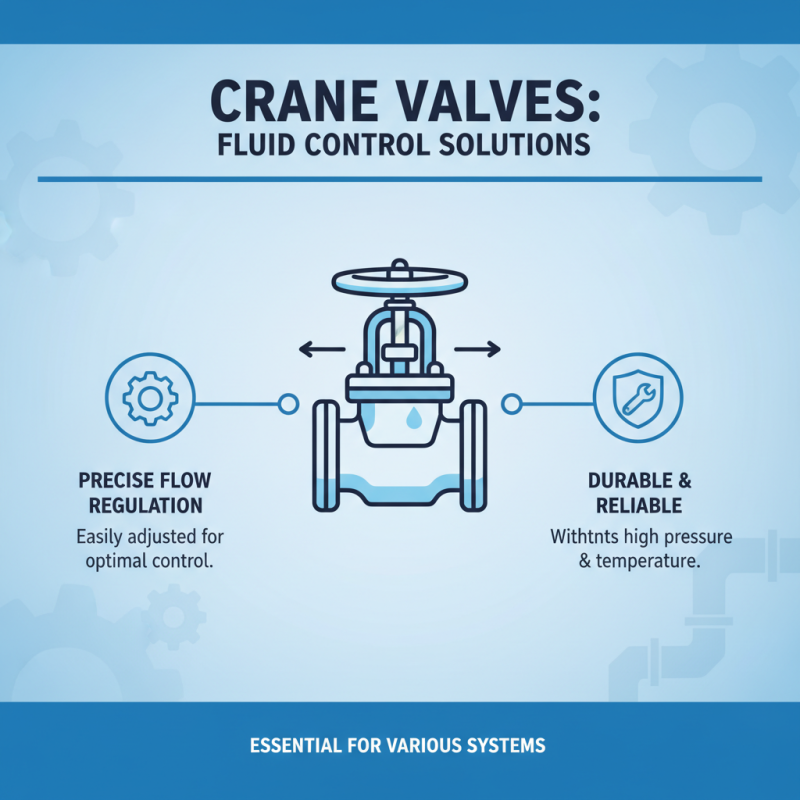

Benefits and Limitations of Using Crane Valves in Systems

Crane valves are crucial components in various fluid systems. They offer several benefits, making them popular choices. One major advantage is their ability to control fluid flow efficiently. These valves can be adjusted easily, providing precise flow regulation. They are also robust, often made from durable materials. This durability ensures that they withstand high pressure and temperature conditions.

However, crane valves have limitations. Their mechanical complexity can lead to potential failures. Regular maintenance is required to ensure optimal performance. Not all systems benefit equally. In some cases, simpler valve types may work better. Moreover, initial installation costs can be higher. This is a concern for tight budgets.

Users must weigh these benefits and drawbacks carefully. Choosing crane valves requires an understanding of the specific application. Ideal sizing and configuration are essential. If miscalculated, even the best valve may underperform. Thus, reflection on system needs is critical. In the end, proper evaluation leads to more effective use of crane valves.

Related Posts

-

Top 10 Crane Valves Types You Should Know About?

-

Best Crane Valves for Optimal Performance and Durability?

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs

-

Top 10 Flow Valves Types and Their Applications Explained?

-

Top Stainless Steel Weld Fittings: A Comprehensive Buying Guide

-

The Essential Guide to Understanding Check Valves: Types, Applications, and Maintenance Tips