Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Top 10 Essential Fittings and Valves You Need for Your Plumbing Projects

In the realm of plumbing, the significance of fittings and valves cannot be overstated. These crucial components serve as the backbone of water distribution systems, ensuring efficient flow control and robust connections. According to a report by the Plumbing Manufacturers International (PMI), the global market for fittings and valves is projected to reach $88 billion by 2025, highlighting an increasing demand driven by construction and infrastructure development. This underscores the necessity for both professionals and DIY enthusiasts to familiarize themselves with the essential types of fittings and valves that can make or break a plumbing project.

As identified by industry expert Dr. Linda Greene, a renowned plumbing systems analyst, "The effectiveness of a plumbing project heavily relies on the quality and suitability of the fittings and valves used." Her assertion reflects the critical nature of proper selection and installation in achieving not only functionality but also long-term reliability. With this in mind, we present the top ten essential fittings and valves that every plumber, whether novice or experienced, should have at their disposal. These components not only enhance the performance of water systems but also contribute to overall workmanship and project durability. Understanding these essentials is key to mastering plumbing tasks and ensuring successful outcomes in any plumbing endeavor.

Essential Pipes: The Backbone of Any Plumbing System

In plumbing systems, essential pipes serve as the backbone that connects various fixtures and manages the flow of water throughout a building. According to the Plumbing-Heating-Cooling Contractors Association (PHCC), up to 80% of plumbing issues can be traced back to inadequate piping. This emphasizes the critical role that quality pipes play in ensuring a reliable and efficient plumbing system. The material of the pipes significantly impacts their longevity and performance, with options ranging from PVC and PEX to copper and galvanized steel, each bringing unique benefits and challenges to different plumbing projects.

Moreover, industry studies indicate that choosing the right pipe material can enhance energy efficiency by as much as 30% when it comes to hot water delivery systems. For example, PEX pipes offer flexibility and resistance to scale and chlorine, which can improve system longevity and reduce maintenance costs. With increasing awareness of the environmental impacts of plumbing systems, more professionals are opting for sustainable materials and methods, aligning with trends that show a growing consumer preference for green building practices. As a result, understanding the properties and applications of various pipes is essential for plumbing professionals aiming to deliver high-quality, sustainable projects.

Understanding the Role of Fittings in Plumbing Projects

Fittings play a pivotal role in plumbing projects, serving as the essential connectors that facilitate smooth fluid movement within pipelines. According to the Plumbing and Drainage Institute, nearly 85% of plumbing issues stem from improper fitting installations or low-quality materials. This highlights the importance of selecting the right fittings to ensure the longevity and efficiency of plumbing systems. Fittings come in various types, including elbows, tees, and couplings, each designed to accommodate specific flow patterns and pressure levels, thereby preventing leaks and system failures.

Moreover, the efficiency of a plumbing system can be significantly influenced by the choice of fittings. A report by the American Society of Plumbing Engineers indicates that using appropriate fittings can enhance flow rates by up to 15%, ultimately leading to improved energy efficiency and reduced water waste. Additionally, with increasing regulations on water conservation, the demand for high-quality, durable fittings that meet industry standards continues to grow. By understanding the critical role that fittings play, plumbers and homeowners can make informed choices that optimize performance and reliability in their plumbing projects.

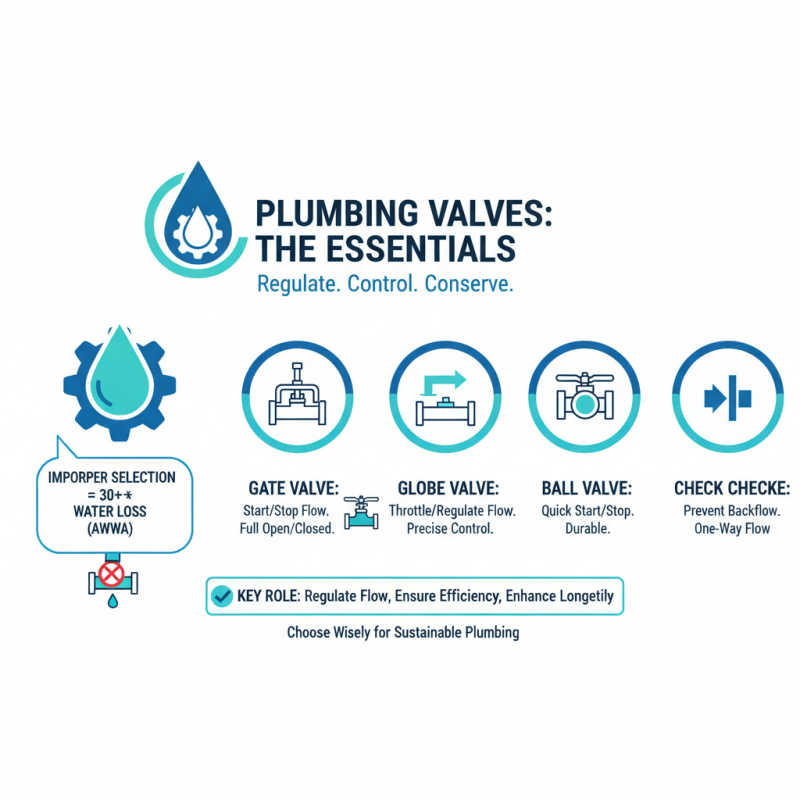

Types of Valves: Ensuring Efficient Flow Control

Valves play a crucial role in plumbing systems by regulating the flow of water and other fluids, ensuring operations run smoothly and efficiently. According to the American Water Works Association, improper valve selection can lead to over 30% of water loss in municipal systems, underscoring the importance of choosing the right valves for your plumbing projects. There are several types of valves, each serving distinct functions that can enhance both performance and longevity. Common types include gate valves, globe valves, ball valves, and check valves, each designed to either start/stop flow, throttle, or prevent backflow.

Efficient flow control is vital in plumbing applications, particularly under varying pressure conditions. Studies indicate that using the appropriate valve type can improve energy efficiency by as much as 25%. For instance, ball valves are favored for their low-pressure drop and ability to maintain flow with minimal turbulence, making them ideal for applications where constant flow is necessary. On the other hand, check valves are indispensable in preventing backflow, which can lead to contamination and costly damage. By understanding the various types of valves and their applications, plumbers can ensure better system performance, compliance with codes, and ultimately, greater customer satisfaction.

Key Factors to Consider When Selecting Plumbing Components

When selecting plumbing fittings and valves, several key factors should be considered to ensure the integrity and efficiency of your projects.

Firstly, the material of the fittings is paramount. Common materials include PVC, copper, and brass, each offering distinct advantages depending on the application. According to a report from the American Society of Plumbing Engineers (ASPE), PVC is typically favored for residential applications due to its cost-effectiveness and resistance to corrosion, while copper is often preferred for its durability and antimicrobial properties in potable water systems.

Another important consideration is the compatibility of fittings with the specific plumbing system being used. The United States Environmental Protection Agency (EPA) emphasizes the significance of ensuring that components are compatible with local regulations and standards to prevent contamination and ensure safety. Moreover, sizing plays a critical role; selecting the correct diameter and thread size is essential to avoid leaks and pressure loss.

Tip: Always consult the specifications of your piping system and local codes to determine the appropriate materials and sizes needed for your project.

Additionally, the type of valve (such as ball, gate, or globe valves) can impact the flow and control of water in your system. Research shows that selecting the right valve not only affects the maintenance and longevity of your plumbing installations but also contributes to energy efficiency and water conservation. A well-chosen valve can improve system performance by up to 30%, according to data from the Plumbing Efficiency Research Coalition.

Tip: Take the time to assess the long-term needs of your plumbing system, as investing in high-quality fittings and valves can save both costs and resources down the line.

Maintenance Tips for Longevity of Fittings and Valves

When it comes to plumbing projects, the longevity of fittings and valves is crucial for maintaining a reliable system. According to the Plumbing Industry Leadership Coalition, replacing worn-out fittings and valves can account for up to 30% of plumbing costs in residential maintenance. To extend their life, regular inspections and maintenance are essential. One key practice is to ensure that fittings are properly installed; even slight misalignments can lead to leaks or pressure loss. A study by the American Society of Plumbing Engineers emphasizes that a tight seal at connection points can significantly reduce the likelihood of leaks, extending the service life of components.

Another important maintenance tip is to regularly check for mineral buildup in fittings and valves, particularly in areas with hard water. The National Association of Home Builders reports that mineral deposits can reduce water flow and pressure, which may necessitate frequent replacements. Using descaling agents and ensuring adequate flow rates can mitigate these issues. Furthermore, periodic lubrication of moving parts in valves can prevent corrosion and ensure smooth operation, ultimately enhancing their durability. By adhering to these maintenance practices, homeowners can not only save on replacement costs but also ensure that their plumbing systems remain efficient and functional for years to come.

Top 10 Essential Fittings and Valves You Need for Your Plumbing Projects

| Fitting/Valve Type | Material | Size (inches) | Application | Maintenance Tips |

|---|---|---|---|---|

| Ball Valve | Brass | 1" | Water Shutoff | Regularly check for leaks. |

| PVC Coupling | PVC | 2" | Drainage Systems | Ensure proper sealing. |

| Pipe Elbow | Copper | 3/4" | Directional Change | Inspect for corrosion. |

| Gate Valve | Bronze | 1.5" | Main Water Supply | Exercise regularly to prevent seizing. |

| Check Valve | Plastic | 3/4" | Backflow Prevention | Keep debris away from valve area. |

| Tee Fitting | Steel | 2" | Branch Connection | Inspect welds and joints. |

| Compression Fitting | Brass | 1/2" | Connecting Pipes | Check for tightness periodically. |

| Pressure Relief Valve | Stainless Steel | 3/4" | Safety Device | Test functionality annually. |

| Adapter Fitting | PVC | 1" | Pipe Transition | Ensure proper fit during installation. |

| Faucet Valve | Ceramic | N/A | Sink Control | Clean aerators regularly. |

Related Posts

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects

-

How to Choose the Right Valves Fittings for Your Plumbing Needs

-

2025 Top 5 Globe Valves You Need to Consider for Your Projects

-

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

-

How to Choose the Right Stainless Steel Ball Valves for Your Application

-

How to Choose the Right Stainless Steel Flanges for Your Project