Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Understanding Flow Valves: How They Optimize Fluid Control with 30% Efficiency Gains in Industry

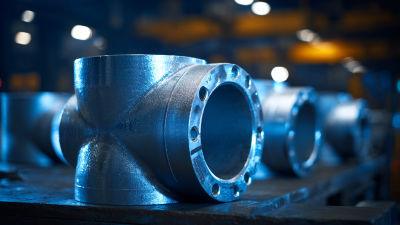

In the quest for enhanced productivity and resource management, industries are increasingly turning their attention to the optimization of fluid control systems. At the forefront of this innovation are flow valves, which play a pivotal role in regulating the flow of liquids and gases across various applications. Understanding flow valves is essential not only for engineers and operators but also for decision-makers seeking to boost operational efficiency.

Recent studies have shown that effective integration of flow valves can lead to remarkable efficiency gains of up to 30%, significantly reducing energy consumption and improving overall system performance.

This article aims to provide a comprehensive guide on how flow valves function, their types, and strategies for implementing them effectively in industrial settings to achieve optimal fluid control. By mastering the utilization of flow valves, businesses can unlock substantial savings and elevate their operational standards.

The Basics of Flow Valves: Types and Applications in Industrial Settings

Flow valves are essential components in various industrial applications, playing a pivotal role in controlling fluid movement and optimizing system efficiency. There are several types of flow valves, including globe valves, ball valves, and butterfly valves, each serving distinct functionalities. For instance, globe valves are well-suited for throttling applications, while ball valves are preferred for on-off control due to their low resistance to flow and quick operation. According to a 2022 industry report by the Global Industry Analysts, the demand for flow valves is projected to grow at a CAGR of 6.3% over the next five years, primarily driven by increased automation in manufacturing processes.

In addition to increasing demand, the efficiency gains associated with optimized flow valve use can be substantial. Recent studies from the International Society of Automation indicate that properly implemented flow control solutions can yield efficiency improvements of up to 30% in fluid handling systems. These enhancements result not only in reduced energy consumption but also in lower operational costs, which are crucial for industries striving to enhance their sustainability metrics. As companies increasingly adopt smart technologies, incorporating advanced flow valve systems will play a significant role in achieving these efficiency targets.

Mechanisms Behind Flow Control: How Valves Regulate Fluid Movement

Flow control is crucial in various industrial applications, and valves play a pivotal role in regulating fluid movement. According to a recent report by the International Society of Automation (ISA), effective valve management can result in efficiency gains of up to 30%. This improvement is primarily achieved through the enhancement of flow characteristics, ensuring that fluids move through systems with minimal turbulence and energy loss. For instance, modern control valves are designed with advanced materials and technologies that adapt to varying pressures and temperatures, thereby maintaining optimal flow rates.

The mechanisms behind flow control involve several technical components, including actuators, positioners, and flow meters. Actuators enable precise valve adjustments, while positioners ensure that the valve’s position aligns with the desired flow rate. A study published in the Journal of Fluid Engineering indicates that integrating intelligent flow control systems can further enhance responsiveness and accuracy, reducing the lead time for adjustments by nearly 20%. By optimizing these mechanisms, industries can improve process reliability and reduce operational costs, ultimately driving overall productivity in fluid management systems.

Efficiency Metrics: Measuring the 30% Gains from Optimized Flow Valves

Flow valves play a crucial role in optimizing fluid control systems across various industries, leading to significant efficiency gains. By precisely regulating the flow rate and pressure of fluids, these valves help reduce waste, minimize energy consumption, and enhance overall system performance. Efficiency metrics often focus on quantifying the improvements engineers achieve through the use of optimized flow valves. Notably, industries adopting advanced valve technologies report up to a 30% increase in efficiency.

To measure these gains accurately, organizations utilize key performance indicators (KPIs) such as energy usage, flow consistency, and pressure drops. By comparing baseline data before implementing optimized flow valves, companies can assess the impact on operational costs and resource utilization. This quantitative approach not only highlights the benefits of valve optimization but also provides a framework for continuous improvement. Ultimately, the implementation of efficient flow valves can transform an industry’s operational strategy, facilitating smarter resource management and enhanced productivity.

Real-World Case Studies: Flow Valves and Their Impact on Industrial Processes

Flow valves play a crucial role in enhancing fluid control within industrial applications, leading to significant efficiency gains. Case studies from various industries illustrate the tangible benefits of implementing advanced flow valve technologies. For instance, a major chemical manufacturing facility reported a 30% increase in throughput by replacing traditional valves with smart flow control systems. This upgrade not only optimized the flow rates but also reduced energy consumption, contributing to lower operational costs and a smaller carbon footprint.

Another notable case involved a water treatment plant that integrated flow valves with real-time monitoring systems. This integration allowed for precise adjustments based on fluctuating demand, resulting in improved resource management. The plant achieved a remarkable reduction in water loss, demonstrating that flow valves can have a profound impact on both efficiency and sustainability in industrial processes. Such real-world examples underscore the importance of flow valves in driving innovations that promote better fluid control, ultimately benefiting industries across the board.

Understanding Flow Valves: Efficiency Gains in Fluid Control

Future Trends in Flow Valve Technology: Innovations Driving Efficiency Forward

The future of flow valve technology is poised for significant advancement as innovations continue to emerge, driving efficiency improvements across various industries. Intelligent control systems integrated into flow valves are becoming increasingly prevalent, allowing for real-time monitoring and adjustments based on dynamic fluid conditions. These systems use sensors and algorithms to optimize flow rates and reduce energy consumption, thereby enhancing overall operational efficiency.

Moreover, advancements in materials science are leading to the development of more durable and corrosion-resistant flow valves. These materials not only extend the lifespan of the valves but also reduce maintenance costs and downtime in industrial applications. Additionally, smart connectivity features, such as IoT-enabled flow valves, facilitate data collection and analytics, providing operators with valuable insights to optimize processes further.

As these innovations gain traction, manufacturers are expected to see efficiency gains of up to 30%, revolutionizing fluid control systems in the coming years.

Related Posts

-

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025

-

How to Choose the Right Flange Gasket for Optimal Sealing Performance: Key Industry Insights

-

How to Choose the Right Valves Fittings for Your Plumbing Needs

-

Unlocking the Advantages of Custom Steel Flanges for Your Next Project: A Comprehensive Guide

-

How to Choose the Right Flange Valves for Your Industrial Needs

-

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights