Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

What Are Gate Valves and How Do They Work?

Gate valves are essential components in various industrial applications. They control the flow of liquids and gases. According to a recent market report, the global gate valve market is projected to reach $5 billion by 2027, demonstrating significant growth. These valves are known for their ability to provide a tight seal, which makes them ideal for on/off control.

The effectiveness of gate valves relies on their simple design. They contain a movable disk, or gate, that fits between two seats. However, their operation is not without challenges. For instance, gate valves can experience issues with leakage and corrosion over time. Reports indicate that more than 30% of valves in certain sectors may require maintenance due to performance decline.

Gate valves are prevalent in water supply and wastewater applications. Their reliability is critical for maintaining infrastructure. Yet, some professionals argue that alternatives, like globe valves, may offer better throttling capabilities. Addressing these trade-offs is crucial as industries evaluate their valve choices. The right decisions can significantly affect operational efficiency and costs.

Definition and Purpose of Gate Valves

Gate valves are essential components in various piping systems. They serve a specific purpose: to control the flow of liquids and gases. Unlike other valve types, gate valves are designed to be fully open or fully closed. This design minimizes friction loss and allows for a smooth flow when the valve is open. The mechanism contains a gate or wedge that can be raised or lowered, providing an effective seal when closed.

The primary use of gate valves is in applications where a straight-line flow is necessary. For instance, they are often employed in water supply systems and oil pipelines. The simplicity of their operation is appealing. However, they are not ideal for throttling. When partially open, they can create turbulence and wear, leading to potential failures. It's crucial to use gate valves appropriately to avoid these issues.

Gate valves are generally easy to install and maintain. Their robust design can handle high pressure and temperature conditions. Some people may overlook routine maintenance. This can lead to corrosion or blockages, causing unnecessary downtime. Awareness of these factors is vital for effective valve performance. Even simple inspections can prevent costly repairs.

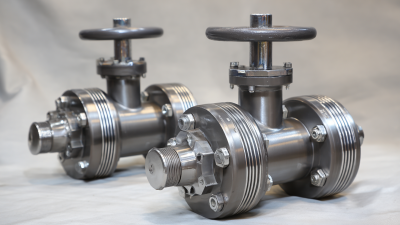

Types of Gate Valves and Their Applications

Gate valves are essential components in various piping systems. They are used to control the flow of liquids and gases. There are several types of gate valves, each designed for specific applications. Understanding these types helps in selecting the right valve for the job.

Wedge gate valves are common in water supply systems. They feature a disc that slides between two seats. This design ensures a tight seal when closed. However, they can be slow to open and close.

Rising stem gate valves are often used in oil and gas pipelines. Their stem moves up and down as the valve opens or closes. These valves can be hard to operate if they become stuck.

Another type is the knife gate valve. This valve uses a sharp blade to cut through solids in a slurry. It is often found in wastewater treatment plants. However, they may not seal completely, leading to leaks. Understanding these nuances is crucial for effective use.

Each type has strengths and weaknesses, which should be considered before making a choice.

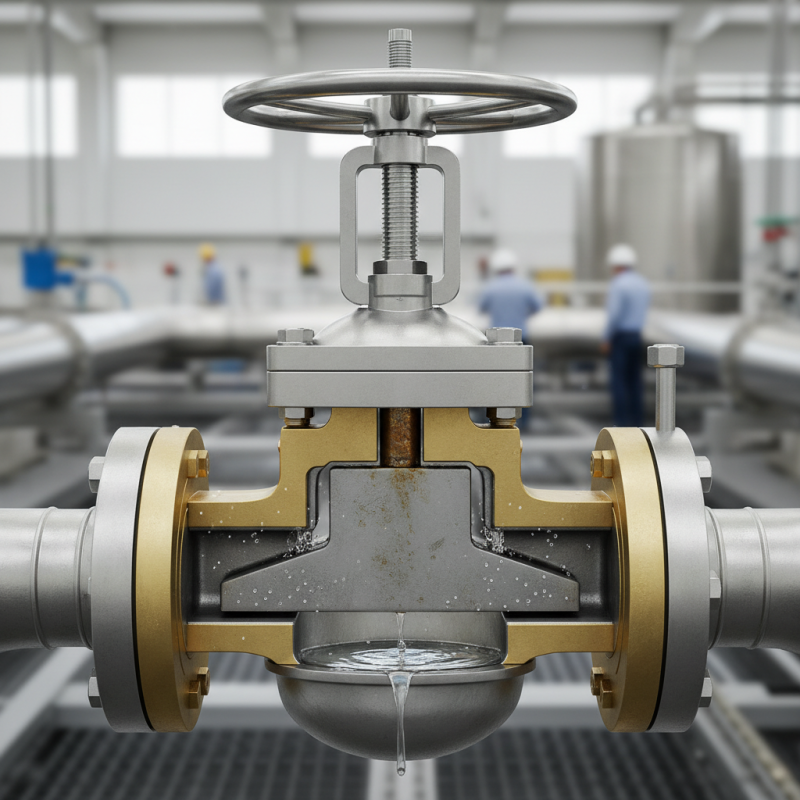

How Gate Valves Operate: Mechanisms and Components

Gate valves are crucial in controlling fluid flow in pipelines. Their operation hinges on a simple but effective design. A wedge-shaped gate sits within the valve body. When the valve is open, the gate is lifted from the flow path, allowing liquids or gases to pass freely. When closed, the gate seals tightly against the valve seat, stopping flow completely. This mechanism is efficient but has limitations.

The components of gate valves include the stem, bonnet, and handwheel. The stem connects the gate to the handwheel, allowing manual operation. The bonnet houses the stem and can sometimes allow for leaks if not maintained properly. While these valves are ideal for on/off control, they are not suitable for throttling. Operating them partially open can lead to erosion and damage.

In summary, gate valves are straightforward devices that rely on a few key components to function effectively. Proper operation requires attention to detail and maintenance. Understanding their mechanics can prevent issues down the line. Although they are built for durability, neglecting them can result in costly failures.

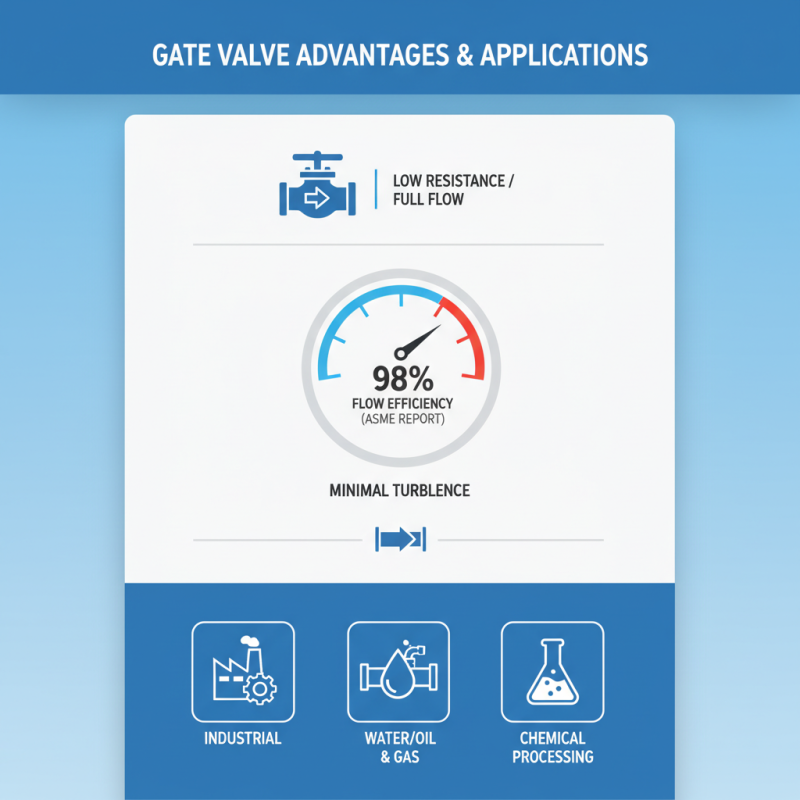

Advantages and Disadvantages of Using Gate Valves

Gate valves are widely used in various industries for their ability to effectively control the flow of liquids and gases. However, they aren’t without complications. One distinct advantage is their low resistance when fully opened. This characteristic allows for a straight flow path, minimizing turbulence. According to a report by the American Society of Mechanical Engineers (ASME), gate valves can achieve up to 98% flow efficiency in optimal conditions.

On the downside, gate valves are slower to operate compared to other valve types. This might be problematic in urgent scenarios. Their design often doesn’t allow for throttling, which means they are not suited for applications requiring flow regulation. Additionally, sealing can become compromised after extensive use. This can lead to leaks and increased maintenance costs. A study from the Valve Manufacturers Association indicates that 15% of valve failures in the field are attributed to improper sealing in gate valves.

In certain situations, gate valves can also suffer from issues related to space. In tight installations, accessing these valves for maintenance can be a challenge. Furthermore, they can be heavy and cumbersome, making installation more labor-intensive. With the increasing demand for reliability in industrial processes, it is crucial to weigh these advantages and disadvantages carefully.

Maintenance and Troubleshooting for Gate Valves

Gate valves are essential components in fluid control systems. Maintenance is crucial to ensure optimal performance. Regular inspections should be scheduled. Check for leaks or corrosion. Any signs of wear must be addressed immediately.

Common issues occur when gate valves are not fully opened or closed. This can lead to flow problems. Sometimes, a valve may become stuck. In such instances, applying a gentle force can help. Lubrication may also aid in easing movement.

Troubleshooting is essential for longevity. If a valve does not seal properly, it could cause leaks. Replacing seals might be necessary. Keep a checklist handy for routine inspections. Document findings for future reference. Taking these steps can save costs down the line.

Gate Valves Pressure Drops vs. Flow Rate

This bar chart illustrates the relationship between flow rate categories and the corresponding pressure drops in gate valves. As flow rate increases, the pressure drop tends to increase, highlighting the importance of selecting the right gate valve for specific applications.

Related Posts

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

The Future of PVC Parts Revolutionizing Manufacturing and Sustainability

-

Comparative Analysis of Steel and Fittings: Selecting the Best Options for Global Buyers

-

Understanding the Role of Steel Fittings in Modern Construction: A Comprehensive Guide