Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

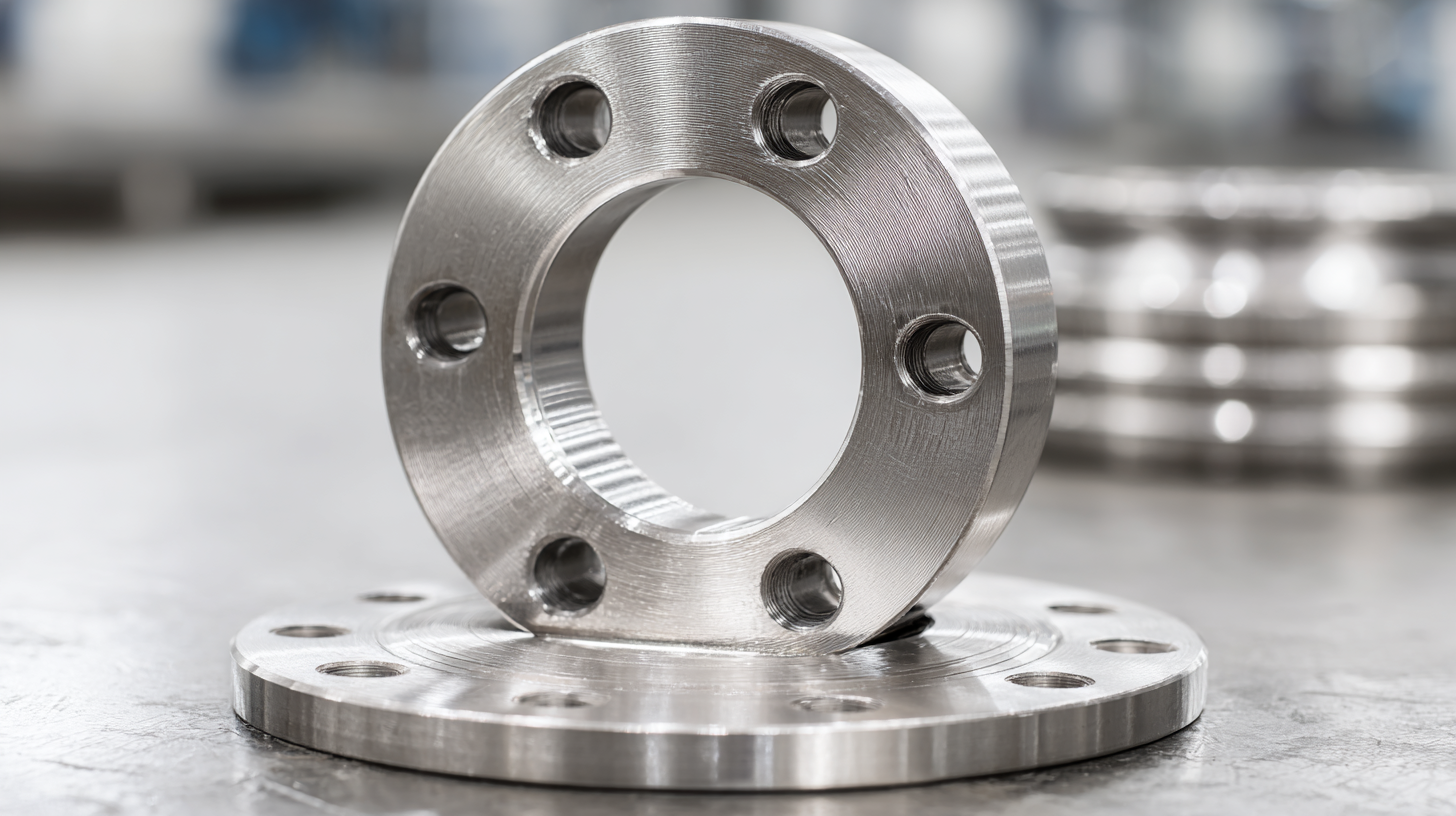

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

The oil and gas industry is a vital sector that heavily relies on high-quality materials and components to ensure efficiency and safety in operations. Among them, stainless steel flanges play a critical role due to their excellent corrosion resistance, durability, and ability to withstand high pressures and temperatures.

According to a recent market report by Research and Markets, the global stainless steel flanges market is projected to grow significantly, with an estimated compound annual growth rate (CAGR) of 5.2% over the next five years, driven by the expanding exploration and production activities in the sector.

Furthermore, the increasing demand for pipeline infrastructure is further elevating the need for reliable stainless steel flanges, which contribute to the overall integrity of oil and gas systems.

This article delves into the impact of stainless steel flanges in the industry, providing essential insights for industry stakeholders and decision-makers.

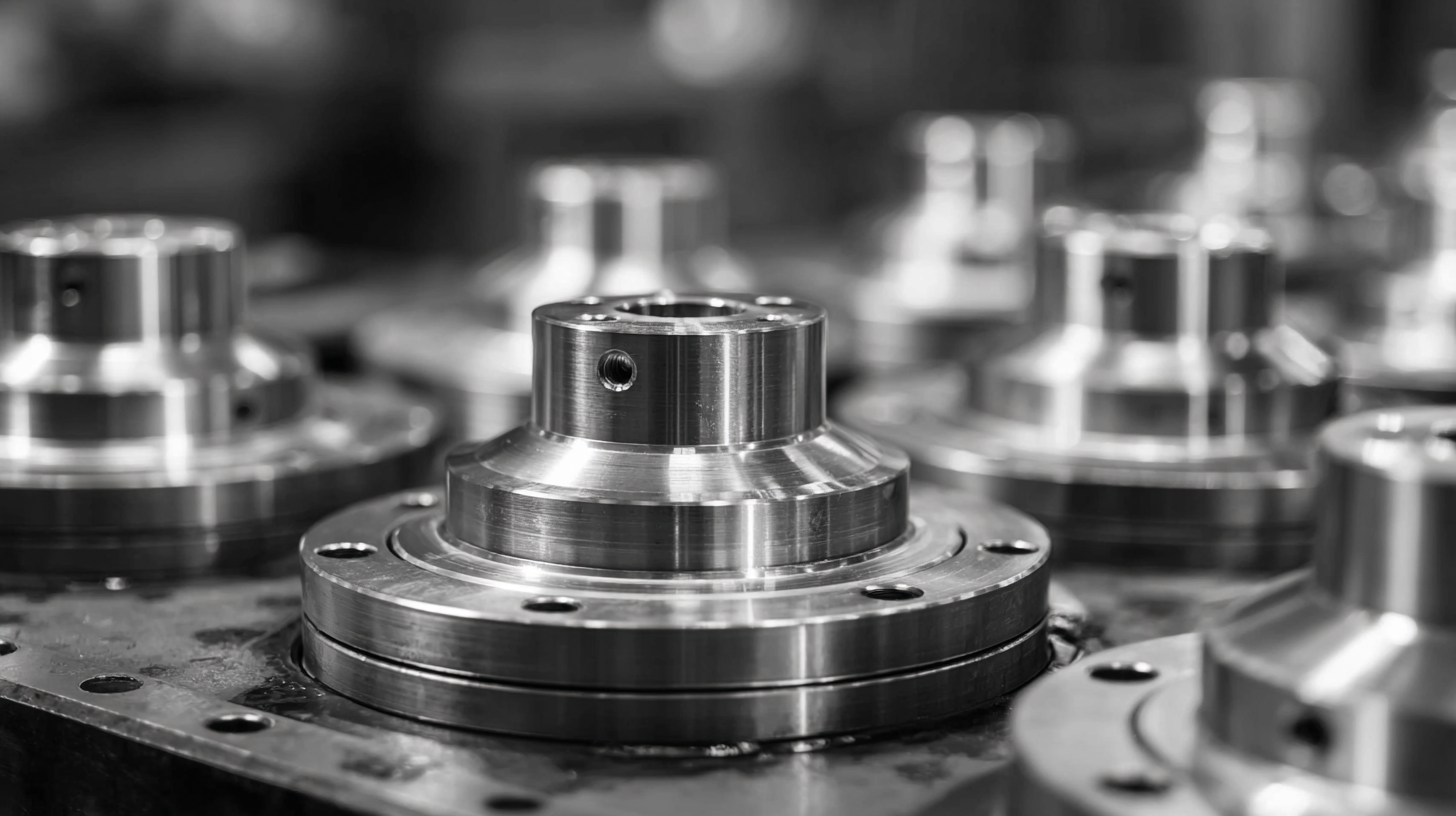

Impact of Stainless Steel Flanges on Operational Efficiency in Oil and Gas Sector

In the oil and gas sector, operational efficiency is paramount, and the choice of materials plays a crucial role. Stainless steel flanges, known for their durability and resistance to corrosion, significantly enhance the reliability of pipelines and other critical infrastructure. According to a recent Market Research Future report, the global stainless steel flange market is projected to grow at a CAGR of over 5% from 2022 to 2029, reflecting the increasing demand for long-lasting, high-performance materials in this industry.

One of the key advantages of stainless steel flanges is their ability to withstand extreme temperatures and pressures, reducing the risk of leaks and failures. A study from the American Society of Mechanical Engineers highlights that the use of stainless steel components can lead to a 30% reduction in maintenance costs, allowing companies to allocate resources more efficiently. This is particularly vital in the oil and gas sector, where unplanned downtime can result in significant financial losses.

Tips: When selecting stainless steel flanges, consider factors such as the grade of stainless steel and the specific environmental conditions they will face. Additionally, regular inspections and maintenance can prolong the lifespan of these components, further enhancing operational efficiency and safety in your projects. By investing wisely in quality materials, companies can achieve both cost savings and improved performance.

Market Demand Analysis for Stainless Steel Flanges in Exploration and Production

The oil and gas industry increasingly demands stainless steel flanges, particularly for wellhead equipment, which includes various types such as conventional wellheads, subsea wellheads, and Christmas tree wellheads. The market size for these essential components is expected to see significant growth, driven by the rising exploration and production activities in emerging offshore and onshore fields. The versatility and corrosion resistance of stainless steel make it a preferred choice for these applications, particularly in harsh environments.

The oil and gas industry increasingly demands stainless steel flanges, particularly for wellhead equipment, which includes various types such as conventional wellheads, subsea wellheads, and Christmas tree wellheads. The market size for these essential components is expected to see significant growth, driven by the rising exploration and production activities in emerging offshore and onshore fields. The versatility and corrosion resistance of stainless steel make it a preferred choice for these applications, particularly in harsh environments.

Tips: When selecting flanges, consider the specific requirements of your project, including pressure ratings and compatibility with other materials. Staying informed about the latest market trends can help you make cost-effective decisions.

As the industry evolves, competition among manufacturers of wellhead components is tightening. The market share dynamics reveal a shift towards companies that innovate with new materials and designs to provide enhanced performance and reliability. Understanding these trends is crucial for stakeholders looking to optimize their operations and maintain a competitive edge in an ever-changing landscape.

Tips: Regularly review supplier performance and product reliability, as these factors can significantly affect operational efficiency. Engaging with suppliers who offer customizable solutions can provide added advantages.

Comparative Study of Flange Material Strengths in Harsh Oil and Gas Environments

In the oil and gas industry, the choice of flange materials is crucial due to the extreme environments in which they operate. A comparative analysis of flange material strengths reveals that stainless steel, particularly types 316L and 304L, exhibit excellent durability and resistance to corrosion, making them suitable for high-pressure applications and environments with aggressive media. According to a report by the International Energy Agency (IEA), stainless steel flanges account for approximately 40% of the flange market share in oil & gas, primarily due to their superior mechanical properties and resilience against sour gas conditions.

Conversely, carbon steel flanges, while more cost-effective, often struggle in environments characterized by high acidity and temperature fluctuations. Data from the American Petroleum Institute (API) indicates that carbon steel flanges show significant degradation after prolonged exposure to harsh saline conditions typical in offshore drilling operations. The tensile strengths of stainless steel flanges can reach upwards of 70,000 psi, compared to around 36,000 psi for carbon steel, highlighting their effectiveness in maintaining structural integrity under stress. As energy companies prioritize safety and efficiency, the trend towards stainless steel flanges is anticipated to continue, driven by their long-term cost benefits and enhanced performance in harsh conditions.

Economic Factors Influencing the Stainless Steel Flange Market Growth

The stainless steel flange market is witnessing significant growth, propelled by various economic factors that shape its trajectory, especially in the oil and gas industry. As reported, the flanges market was valued at approximately USD 5.7 billion in 2024 and is anticipated to grow at a compound annual growth rate (CAGR) of over 5.8% from 2025 to 2034. This growth is largely influenced by the rising global energy demands, which necessitate the enhanced application of stainless steel flanges in critical infrastructure projects.

Moreover, the global flanges market is expected to reach an estimated USD 9.8 billion by 2025, further expanding to USD 17.9 billion by 2035, with an impressive CAGR of 6.2% during this period. The increasing focus on sustainable energy solutions and the adoption of advanced technologies in flange manufacturing are pivotal economic factors driving this market expansion. These trends underscore the importance of stainless steel flanges as essential components in maintaining the efficiency and reliability of oil and gas operations, reflecting their growing significance within the industry.

Key Trends in the Adoption of Stainless Steel Flanges in Global Oil and Gas Projects

The adoption of stainless steel flanges in global oil and gas projects has been gaining momentum, driven by their durability, corrosion resistance, and cost-effectiveness. According to a recent report by MarketsandMarkets, the global stainless steel flange market is projected to reach USD 4.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%. This growth is largely attributed to an increase in offshore drilling activities and the rising demand for energy, which necessitates reliable piping systems that can withstand harsh environmental conditions.

In addition, trends indicate a shift towards the use of higher-grade stainless steel alloys, such as 316L and duplex stainless steel, to enhance the longevity and performance of flanges in extreme conditions. A study published in the Journal of Petroleum Technology highlights that projects utilizing these advanced materials report up to 30% less maintenance downtime, substantially reducing operational costs.

Tips: When selecting stainless steel flanges for a project, consider the specific environmental conditions and the type of fluids being transported. Conducting a thorough material compatibility assessment can lead to significant cost savings in maintenance and replacement. Furthermore, it's advisable to stay updated on the latest market trends and technological advancements to ensure optimal performance and compliance with industry standards.

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry

| Region | Market Share (%) | Growth Rate (CAGR %) | Key Application Areas |

|---|---|---|---|

| North America | 40% | 4.5% | Pipeline Construction, Refining |

| Europe | 30% | 3.8% | Oil & Gas Extraction, Offshore Platforms |

| Asia-Pacific | 20% | 5.2% | Natural Gas Processing, Petrochemicals |

| Middle East & Africa | 10% | 4.0% | Exploration, Oil Field Services |

Related Posts

-

7 Best Flange Gasket Options You Didn't Know Existed

-

Exploring the Rise of Steel Flanges in 2025 China Import Export Trends at the 138th Canton Fair

-

How to Choose the Right Stainless Valves for Your Industrial Applications

-

Unlocking the Advantages of Custom Steel Flanges for Your Next Project: A Comprehensive Guide

-

How to Choose the Right Stainless Fittings for Your Industrial Needs

-

The Ultimate Guide to Understanding Steel Flanges: Types, Uses, and Industry Insights