Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

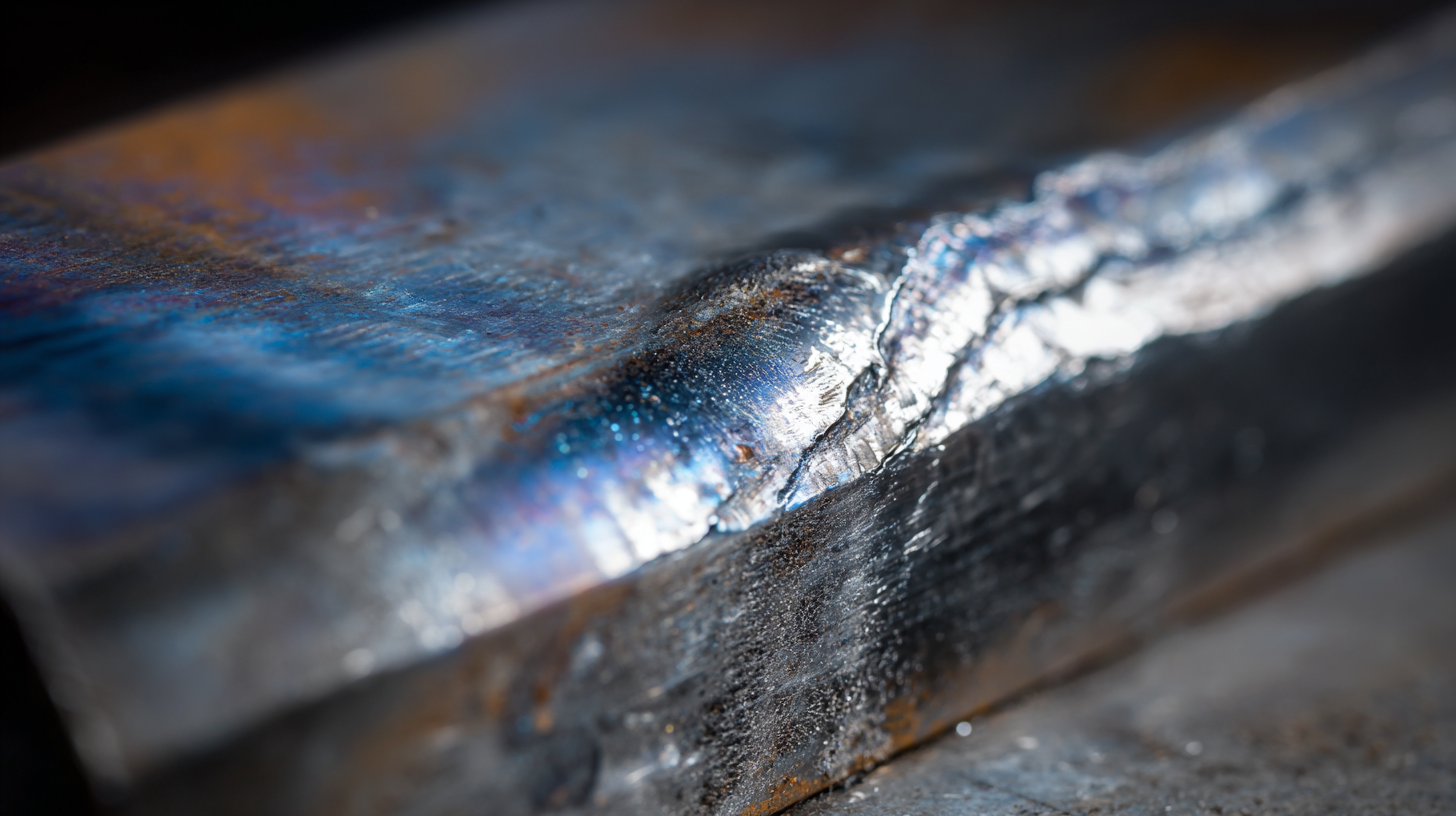

How to Achieve Perfect Weld Bend Specifications for Your Projects

In the realm of welding, achieving perfect weld bend specifications is crucial for ensuring the structural integrity and longevity of various projects, particularly in industries such as construction and manufacturing. According to a study conducted by the American Welding Society (AWS), nearly 60% of all welding failures can be attributed to inadequate weld quality, with improper bend tests being a significant factor. Weld bend tests, which assess the ductility and soundness of a weld, are essential for meeting industry standards and customer expectations. As trends in welding technology evolve, understanding how to produce optimal weld bend outcomes becomes increasingly important. This blog will delve into effective techniques and best practices, supported by relevant data, to help professionals consistently achieve the stringent specifications necessary for successful welding projects.

Understanding Weld Bend Specifications: Key Factors for Success

When it comes to achieving perfect weld bend specifications, understanding the key factors that influence success is crucial. Weld bend tests are essential for verifying the integrity and strength of welded joints, and several factors can affect the outcomes. Material selection, for example, plays a significant role in determining how a weld will behave under stress. Choosing compatible materials that match or complement each other ensures better fusion and minimizes weaknesses in the joint.

In addition to materials, technique and equipment also impact weld bend specifications. The choice of welding method, such as MIG or TIG, can produce different results based on the joint design and intended application. Proper pre-weld preparation, including cleaning and fitting, is essential to achieve a sound weld. Furthermore, monitoring parameters like heat input and travel speed during the welding process can help create a more uniform structure that resists bending and deformation. By focusing on these fundamental factors, welders can achieve the desired specifications, ensuring the reliability and strength of their welded projects.

How to Achieve Perfect Weld Bend Specifications for Your Projects

| Specification Component | Description | Impact on Weld Quality | Recommended Values |

|---|---|---|---|

| Bend Radius | The measured radius of the bend in the weld | Affects stress distribution and risk of cracking | T ≥ 1.5 x material thickness |

| Weld Size | The overall dimensions of the weld bead | Larger sizes increase strength but can create heat distortion | Equal to or greater than the base material thickness |

| Material Type | The composition of the metals being welded | Different materials require specific welding techniques | Refer to the welding procedure specification |

| Heat Input | The amount of heat applied during welding | High heat can lead to distortion and reduced mechanical properties | Maintain within specified range (e.g., 10-30 kJ/h) |

| Welding Speed | Rate of travel of the welding gun | Influences bead shape and penetration | Follow manufacturer recommendations based on material |

Top 5 Techniques for Achieving Consistent Weld Quality

Achieving consistent weld quality is crucial for any project involving metal fabrication. According to a report by the American Welding Society, about 40% of all rework in welding projects stems from poor quality welds. To counter this issue, implementing effective techniques can significantly improve the outcomes of welding processes.

One of the top techniques for ensuring optimal weld bend specifications is the use of proper joint design. A well-designed joint not only enhances the strength of the weld but also minimizes stress concentration, as highlighted in a study conducted by the International Institute of Welding. Another key method involves maintaining consistent heat input during welding. The Welding Research Council notes that fluctuations in heat can lead to distortion and defects, which ultimately compromise the integrity of the weld. Monitoring and controlling the preheat and interpass temperature can help achieve uniformity, leading to higher quality welds consistently.

Lastly, adopting advanced welding technologies, such as robotic welding, can lead to better precision and repeatability. A survey by the Fabricators & Manufacturers Association revealed that companies utilizing these technologies reported a 30% reduction in defects compared to traditional methods. By integrating these techniques, fabricators can ensure they meet the required weld bend specifications, resulting in stronger and more reliable end products.

Weld Bend Specifications Comparison

This bar chart illustrates the bend strength achieved using five different welding techniques. Each technique shows varying degrees of strength, highlighting the effectiveness of optimizing welding parameters to achieve perfect weld bend specifications.

3 Common Mistakes to Avoid in Weld Bend Testing

When it comes to achieving perfect weld bend specifications, avoiding common pitfalls in weld bend testing is crucial. One prevalent mistake is inadequate preparation of the test specimens. According to a report by the American Welding Society, nearly 30% of weld failures can be attributed to improper specimen preparation. This can include not removing surface contaminants or not adhering to standard dimensions, both of which can lead to inaccurate testing results. Ensuring that specimens are clean and properly sized is the first step toward reliable assessments.

Another common error involves overlooking the importance of following industry-standard testing procedures. The International Organization for Standardization (ISO) specifies detailed methodologies for conducting weld bend tests, including load applications and strain rate considerations. Ignoring these protocols can result in misleading data. A study published in the Journal of Materials Science indicated that deviations from standard testing conditions could alter the bend strength readings by as much as 25%, making it imperative to stick to recognized practices. By being aware of these mistakes, professionals can enhance the accuracy of their weld bend testing and achieve the desired specifications for their projects.

Essential Tools for Perfecting Your Bend Test Results

When it comes to welding projects, achieving perfect weld bend specifications is crucial for ensuring the integrity and reliability of your structures. One of the most important aspects of this process is utilizing the right tools for your bend tests. Essential tools can make a significant difference, not only in accuracy but also in the overall quality of your welds.

Firstly, a high-quality bend test machine is necessary to apply consistent pressure and measure the degree of deformation precisely. This equipment should accommodate various test samples and materials, allowing for versatile testing conditions. Additionally, gauges and measuring devices are indispensable in determining the exact angles and measurements required for compliance with specifications. For best results, digital measuring tools can offer enhanced precision compared to their analog counterparts.

Firstly, a high-quality bend test machine is necessary to apply consistent pressure and measure the degree of deformation precisely. This equipment should accommodate various test samples and materials, allowing for versatile testing conditions. Additionally, gauges and measuring devices are indispensable in determining the exact angles and measurements required for compliance with specifications. For best results, digital measuring tools can offer enhanced precision compared to their analog counterparts.

Moreover, proper fixture setups are paramount to ensuring that all samples are tested uniformly. Investing in adjustable or modular fixtures can facilitate adjustments for different types of welds and materials, ensuring that each test is fair and standardized. By equipping yourself with these essential tools and ensuring they are properly maintained, you’ll be set up to perfect your bend test results and guarantee the reliability of your welds in any project.

The Role of Material Selection in Weld Bend Performance

In the pursuit of achieving perfect weld bend specifications, material selection plays a crucial role in determining the performance and reliability of welded joints. According to a report by the American Welding Society, materials with high ductility tend to exhibit improved bend performance, as they can absorb energy and deform without fracturing. For example, low-alloy high-strength steels are favored in many applications due to their excellent strength-to-weight ratio and enhanced weldability, leading to projects that meet stringent industry standards.

Furthermore, the choice of filler material is equally significant. The Welding Industry Association states that using a filler material that is compatible with the base metal not only enhances the strength of the weld but also contributes to proper ductility and toughness. This compatibility helps in mitigating issues such as weld cracking and ensures that the welded joints maintain their integrity under stress. Selecting materials that complement each other can lead to optimal weld bend performance, which is essential for applications ranging from structural fabrication to the manufacturing of pressure vessels.

Related Posts

-

How to Choose the Right Stainless Fittings for Your Industrial Needs

-

Comparative Analysis of Steel Flanges: Key Specifications & Market Trends for Global Buyers

-

Ultimate Checklist for Choosing the Right Flanges and Fittings for Your Project

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

The Future of PVC Parts Revolutionizing Manufacturing and Sustainability