Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

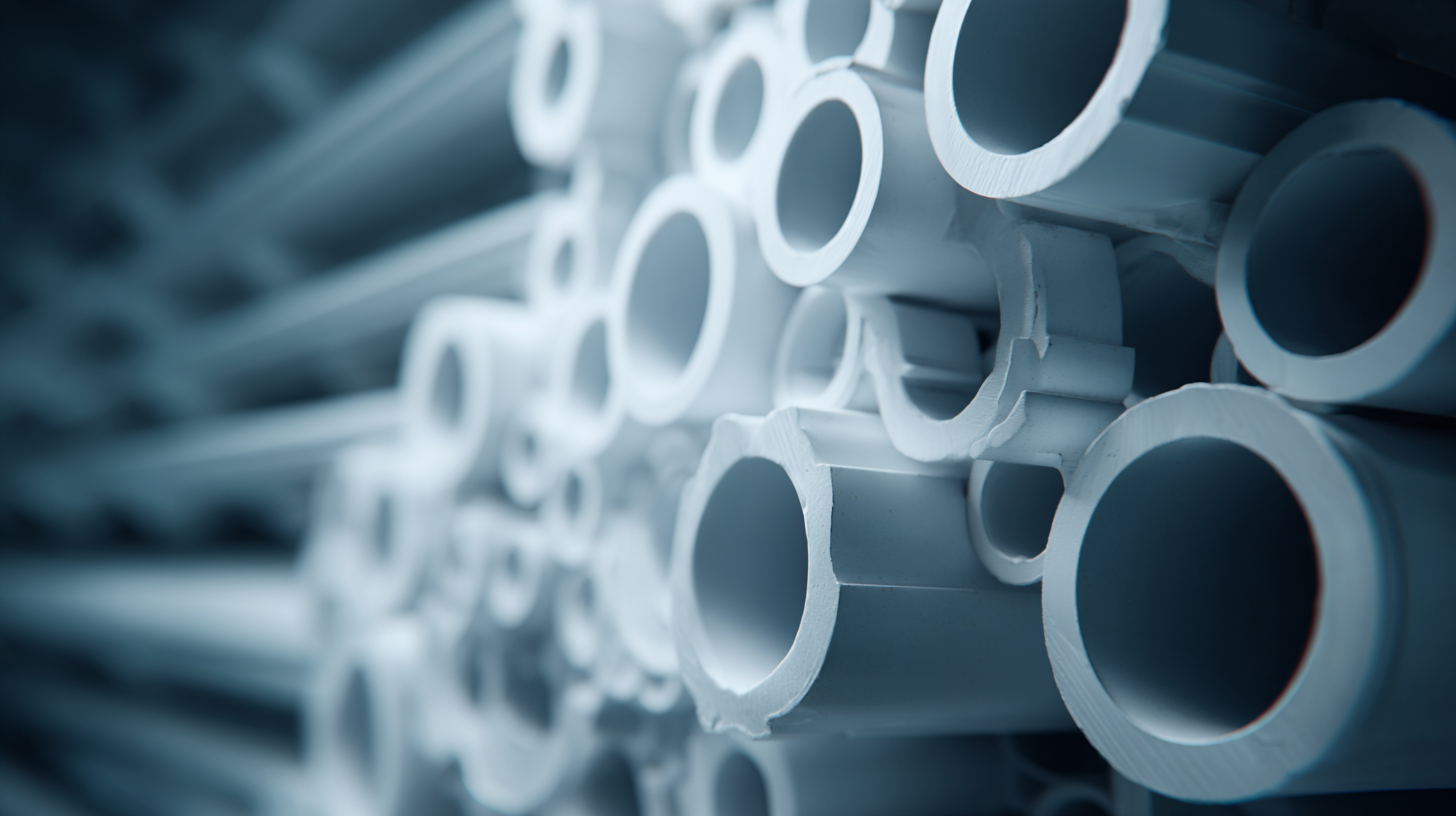

Top PVC Parts in 2025 Innovations and Trends for Your Projects

As we move toward 2025, the advancements in the PVC parts industry promise a transformative impact on various projects across multiple sectors. Leading expert in the field, Dr. Emily Tran, emphasizes this dynamic shift, stating, "The innovations in PVC parts are not just enhancements; they represent a pivotal change in how we approach design and functionality." This transformation is driven by the increasing demand for sustainable materials and efficient manufacturing processes that cater to the evolving needs of industries.

The trends influencing PVC parts in the upcoming years are multifaceted, including the integration of smart technologies and eco-friendly formulations. With applications ranging from construction to automotive, the versatility of PVC parts continues to expand. Innovations such as 3D printing and enhanced recycling methods are set to redefine the standards of performance and sustainability. As project managers and manufacturers prepare for these changes, understanding the latest trends in PVC parts becomes essential for staying competitive and effective in today's fast-paced market.

In this evolving landscape, staying informed about the latest innovations will provide a significant advantage. Embracing these trends will not only improve project outcomes but also contribute to a more sustainable future for the PVC parts industry.

Innovative PVC Materials Transforming Project Design in 2025

As we look forward to 2025, innovative PVC materials are set to significantly reshape project design across various sectors. According to a recent report by the PVC Industry Association, the global demand for PVC is expected to reach 50 million tons by 2025, driven by advancements in manufacturing technologies and eco-friendly formulations. This surge in popularity is attributed not only to PVC's cost-effectiveness but also its versatility in applications ranging from construction to automotive components.

One emerging trend is the use of bio-based PVC, which incorporates renewable resources, cutting down on fossil fuel reliance. A study from the International Polymer Science Congress indicates that bio-based PVC could reduce carbon emissions by up to 30% compared to traditional formulations. This innovation aligns with the greater industry push towards sustainability, influencing architectural design to embrace more environmentally responsible materials. As designers and engineers become more aware of these advancements, they will likely integrate these materials into their projects, paving the way for a greener future in construction and design.

Sustainable Practices: Eco-Friendly PVC Solutions for Future Projects

The demand for sustainable practices in the PVC industry is on the rise as environmental concerns become increasingly prominent. According to a report by Research and Markets, the global market for eco-friendly PVC is anticipated to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This shift is largely driven by the increasing adoption of recycled materials and innovative manufacturing techniques that minimize waste and energy consumption. As companies seek to align their products with sustainable practices, eco-friendly PVC solutions are being developed to cater to this growing market.

Innovations such as bio-based PVC and advanced recycling technologies are emerging as vital alternatives. A study by the Vinyl Institute highlights that using recycled PVC can reduce greenhouse gas emissions by up to 80% compared to traditional methods. Furthermore, the implementation of sustainable production practices not only helps mitigate environmental impacts but also enhances brand reputation and consumer trust. By integrating eco-friendly PVC solutions in their projects, companies can ensure that their operations are both resilient and responsible, setting a benchmark for sustainability in the industry.

Smart Technology Integration: IoT and PVC Components in 2025

The integration of smart technology into PVC components in 2025 is poised to transform various industries, offering enhanced functionality and efficiency in projects. The Internet of Things (IoT) is a key player in this evolution, enabling seamless communication between PVC parts and digital networks. This connectivity allows for real-time monitoring and control, which is particularly beneficial in manufacturing, construction, and infrastructure management.

As more designers and engineers leverage IoT-enabled PVC components, projects will benefit from increased automation and data collection. For instance, PVC pipes equipped with sensors can provide feedback on flow rates and pressure, helping to detect leaks or maintenance needs before they escalate into significant issues. Additionally, smart homes utilizing advanced PVC fittings will offer homeowners the ability to manage energy consumption and improve overall convenience through integrated systems. This trend not only enhances project performance but also aligns with sustainability goals, as smarter materials contribute to efficient resource usage and waste reduction.

Top PVC Parts in 2025 Innovations and Trends for Your Projects

| Component Type | Innovation Description | IoT Integration | Projected Growth (%) |

|---|---|---|---|

| PVC Pipes | Smart pipes with sensors for real-time monitoring | Temperature and pressure monitoring | 10% |

| PVC Fittings | Modular design for easy assembly and customization | Compatibility with smart home systems | 12% |

| PVC Sheets | Enhanced durability with lightweight properties | Integration with smart display technologies | 8% |

| PVC Flooring | Eco-friendly solutions with antimicrobial properties | Motion sensors for energy savings | 15% |

| PVC Enclosures | Weather-resistant designs for various applications | Remote monitoring via mobile apps | 9% |

Customization and Versatility: The Future of PVC Products in Various Industries

The future of PVC products is marked by an increasing emphasis on customization and versatility across various industries. According to a 2023 market report by Smithers, the global PVC market is projected to reach $75 billion by 2025, driven largely by innovations in manufacturing processes that allow for more tailored applications. Businesses are now able to request specific formulations of PVC that cater to unique requirements, such as enhanced UV resistance or improved chemical stability, making these materials suitable for a broader range of uses.

In sectors such as construction, automotive, and healthcare, customizable PVC products are becoming essential due to their lightweight, durable, and moisture-resistant properties. The construction industry alone is expected to account for nearly 45% of the PVC market by 2025, facilitating innovations like modular designs that streamline building processes. Additionally, a report from Technavio highlights that the demand for PVC in automotive applications is surging, anticipating a growth of 5% annually, driven by the material's adaptability to varied design aesthetics and compliance with environmental regulations. As industries evolve, the ability to customize PVC products will play a crucial role in providing functionality while meeting specific performance standards.

Top PVC Parts Innovations and Trends in 2025

Emerging Trends in PVC Manufacturing: Efficiency and Sustainability Enhancements

The emerging trends in PVC manufacturing for 2025 highlight a significant shift towards efficiency and sustainability. With increasing global concerns regarding environmental impact, manufacturers are investing in innovative processes that enhance the sustainability of PVC products. One notable trend is the development of recyclable PVC solutions. This not only reduces waste but also meets the growing consumer demand for eco-friendly packaging options. As the PVC packaging film market is projected to grow substantially, the focus on recyclable materials is likely to play a crucial role in shaping future market dynamics.

Additionally, advancements in manufacturing techniques are aimed at optimizing energy use and reducing emissions. The efficiency enhancements in PVC production processes contribute to lower operational costs and a smaller carbon footprint. As industries increasingly turn towards sustainable practices, the push for efficient PVC manufacturing is expected to foster a more circular economy. This combination of innovation and sustainability will not only benefit manufacturers but also align with consumer expectations in a rapidly evolving market.

Related Posts

-

The Future of PVC Parts Revolutionizing Manufacturing and Sustainability

-

The Essential Guide to Choosing the Right Stainless Flanges for Your Projects

-

The Ultimate Guide to Understanding Steel Flanges: Types, Uses, and Industry Insights

-

Understanding the Role of Steel Fittings in Modern Construction: A Comprehensive Guide

-

Exploring Alternative Weld Fittings: Innovative Solutions for Global Procurement Needs

-

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025