Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Why Are Stainless Steel Valves Essential for Your Plumbing Needs?

In today’s plumbing landscape, the importance of stainless steel valves cannot be overstated. Mark Thompson, a leading expert in plumbing solutions, emphasizes, "Stainless steel valves offer reliability and durability that other materials can't match." This rings true as many homeowners and professionals face issues with corrosion and wear in their systems.

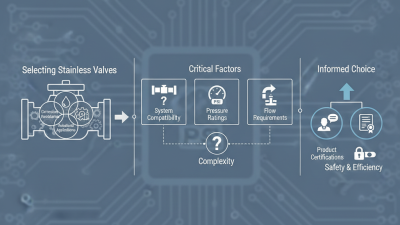

Stainless steel valves stand out for their resistance to rust and high temperatures. They are used in various applications, from residential plumbing to industrial settings. This versatility makes them essential. However, selecting the right valve can be challenging. Factors such as size, pressure rating, and compatibility must be considered. Many overlook these aspects, leading to potential failures.

While stainless steel is robust, it is not infallible. Proper installation and maintenance are key. A neglected valve can lead to leaks and costly repairs. Understanding the role of stainless steel valves is crucial for anyone involved in plumbing. Balancing quality and functionality will prevent unforeseen issues.

The Importance of Stainless Steel Valves in Modern Plumbing Systems

Stainless steel valves play a crucial role in modern plumbing systems. These valves resist corrosion and provide durability. According to industry reports, stainless steel can last over 50 years with proper maintenance. Their resistance to rust and staining makes them ideal for various applications. In environments where water quality matters, stainless steel stands out.

Using stainless steel valves can improve water efficiency. They reduce leaks and maintain optimal pressure. Studies indicate that leaky pipes waste up to 10,000 gallons of water per year for an average household. Choosing the right valve sizes is essential. Oversized valves can lead to turbulence, while undersized ones cause pressure drops.

Tip: Regular maintenance checks can extend the lifespan of your valves. Inspect for rust or wear every six months. Another tip is to ensure proper installation. Incorrectly installed valves can lead to significant problems down the line. Lastly, don’t overlook the importance of quality over cost. A cheaper option might save money upfront but can lead to costly repairs.

Key Properties of Stainless Steel: Corrosion Resistance and Durability

Stainless steel valves are vital in plumbing due to their superior properties. One of the most notable qualities is corrosion resistance. Unlike other metals, stainless steel withstands harsh environments. For example, it can tolerate moisture, chemicals, and extreme temperatures without deteriorating. This quality ensures that the valves remain functional over time, reducing the need for frequent replacements.

Durability is another critical property of stainless steel. These valves can handle high pressure and maintain integrity under stress. Many plumbers choose stainless steel because it means fewer repairs and less downtime. However, some might overlook the initial investment. While stainless steel costs more upfront, long-term savings become evident. It's essential to weigh these factors carefully when making a decision.

Consider the installation process, too. Improper installation can negate the benefits of stainless steel. It requires precise fitting to avoid leaks. A small oversight can lead to significant issues down the line. Being aware of these intricacies ensures effective functioning of plumbing systems, highlighting the importance of quality materials and workmanship.

Cost-Effectiveness of Stainless Steel Valves Over Time

When considering plumbing solutions, the cost-effectiveness of stainless steel valves shines through. An industry report from the American Society of Civil Engineers indicates that stainless steel valves offer a longer lifespan than traditional materials. Specifically, they can last over 15 years with minimal maintenance. This durability translates into fewer replacements, which saves homeowners significant amounts over time.

Additionally, stainless steel valves resist corrosion, reducing the likelihood of leaks and failures. According to a study by the International Water Association, stainless steel systems can reduce maintenance costs by up to 30%. While the initial investment may be higher, the long-term savings often outweigh upfront expenses. It's crucial to analyze the lifetime costs rather than just the sticker price.

However, not all projects may warrant stainless steel. For example, in low-pressure systems, cheaper materials could suffice. Evaluating specific plumbing needs can reveal whether stainless steel is the right choice. Balancing immediate and future costs is essential for smart plumbing investments.

Applications of Stainless Steel Valves in Residential and Industrial Plumbing

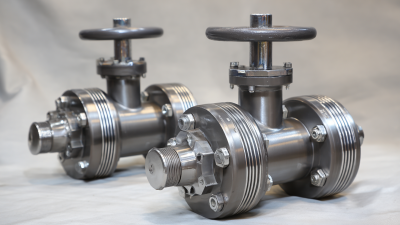

Stainless steel valves play a crucial role in both residential and industrial plumbing. In homes, these valves are often used in water supply systems. Their resistance to corrosion makes them ideal for long-lasting use. The durability of stainless steel ensures fewer leaks and less maintenance over time.

In industrial plumbing, stainless steel valves handle various fluids and gases. They withstand high temperatures and pressures, which is essential in manufacturing settings. These valves help in the smooth operation of machinery and systems. However, choosing the right size and type is vital. A miscalculation can lead to inefficiencies.

Tip: Regularly inspect your valves for signs of wear. They can wear down over time. Small leaks can lead to significant water loss.

When selecting stainless steel valves, consider the environment. Some areas have harsher conditions that may affect performance. Always research the specific requirements for your application. Improper installation can lead to future problems, so be thorough.

Tip: Consult with a professional. They can provide insights specific to your needs. Taking shortcuts might save time now but can lead to costly repairs later.

Industry Standards and Regulations for Stainless Steel Valves in Plumbing

Stainless steel valves play a crucial role in plumbing systems. They meet industry standards for safety and performance. Regulations dictate their material and design, ensuring durability. These valves resist corrosion, making them ideal for water systems. Health standards also require plumbing materials to prevent contamination.

When choosing valves, ensure they comply with local codes. Some regions have specific requirements for materials. It’s best to consult your local regulations to avoid mistakes. Always look for certifications from recognized bodies. This guarantees quality and reliability.

Tip: Regularly inspect your plumbing for any signs of wear. Monitor valve performance and address issues early. A small leak can lead to significant damage. Keep records of maintenance. This may help in the long run and save costs.

Related Posts

-

Top Stainless Steel Valves Types and Their Applications?

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

How to Choose the Best Stainless Valves for Your Needs?

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

The Essential Guide to Understanding Check Valves: Types, Applications, and Maintenance Tips

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs