Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Top 10 Flow Valves Types and Their Applications Explained?

Flow valves are essential components used in various industrial applications. They control the flow of liquids and gases in systems. Understanding different types of flow valves is crucial for effective operation and maintenance.

In this guide, we will explore the top 10 flow valve types. Each type has unique features and applications. For example, gate valves provide tight sealing. On the other hand, globe valves offer precise flow regulation. These distinctions matter when choosing the right valve for specific needs.

However, selecting a flow valve can be challenging. Some may overlook the importance of compatibility with the system. Others might prioritize cost over quality. Reflecting on these choices can lead to better decisions in the long run. This overview will shed light on the options available and help clarify your understanding of flow valves.

Types of Flow Valves: An Overview of Key Categories

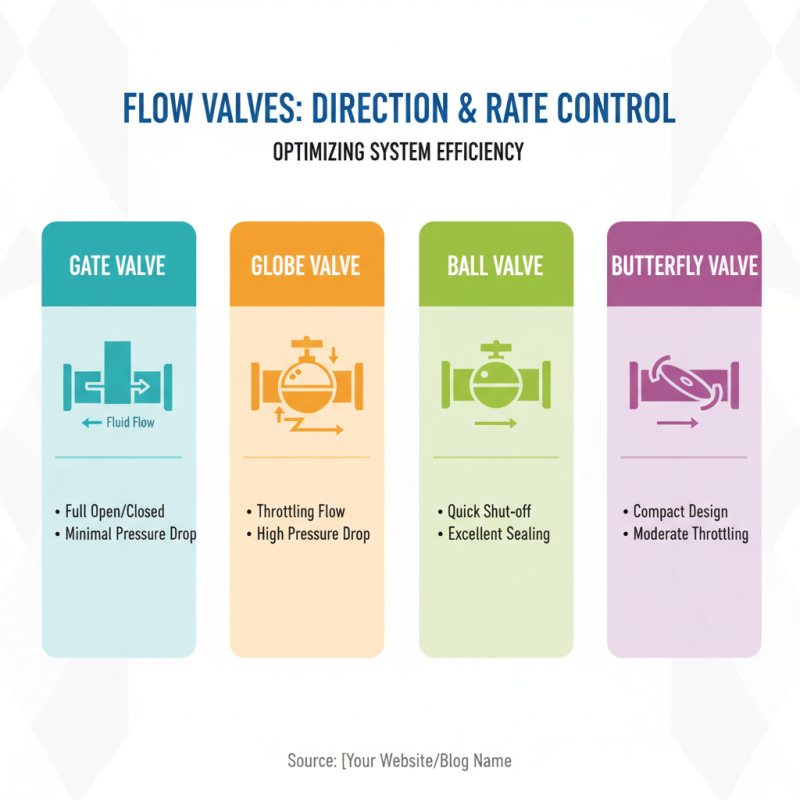

Flow valves play a crucial role in controlling the direction and rate of fluid movement. Understanding the types of flow valves can significantly impact system efficiency. A major classification includes gate, globe, ball, and butterfly valves. Each has unique characteristics suited for specific applications.

Gate valves are primarily used for on/off control. They provide minimal flow resistance when fully open. However, they are not ideal for throttling. Globe valves are often chosen for flow regulation. They manage flow well but can create pressure drops.

**Tip:** Always consider the maximum flow rate in your application. It helps in choosing the right valve type for durability and performance.

Ball valves are efficient for quick shut-off. They are simple and provide a tight seal. Unfortunately, prolonged use in throttling can wear them down. Butterfly valves are lightweight and require less space. They are suitable for handling large volumes but need proper installation to prevent leaks.

**Tip:** Regular maintenance can prevent unexpected breakdowns. Check for leaks or signs of wear periodically.

Understanding these types can help in selecting the right valve for various applications. Each valve has specific strengths and weaknesses. It is essential to reflect on your system's requirements before making a choice.

Understanding the Functionality of Each Flow Valve Type

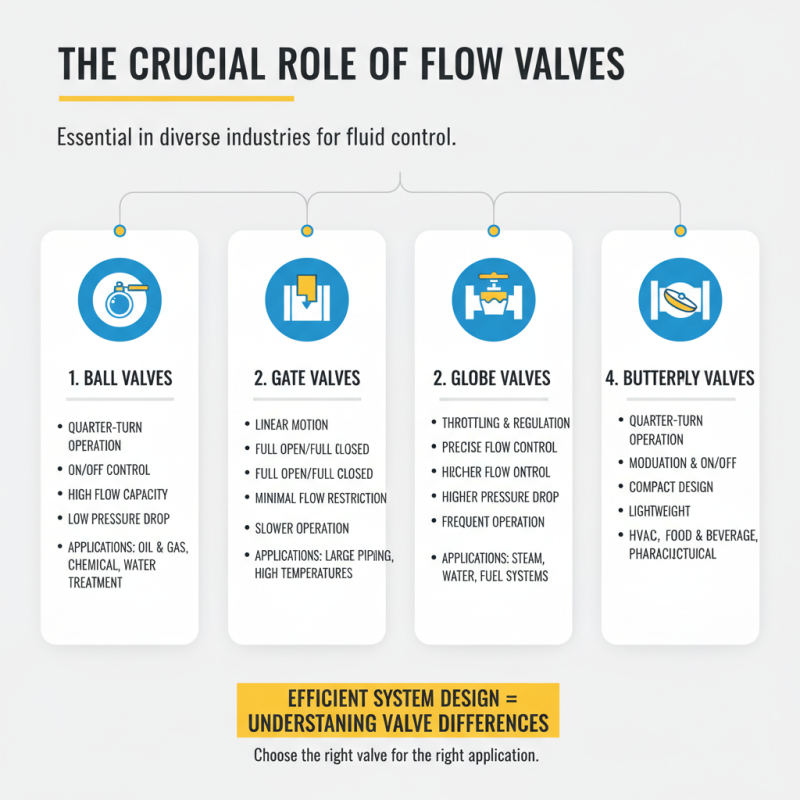

Flow valves play a crucial role in various industries. Their design influences the control of fluid flow. Each type has unique functionalities, making them suitable for specific applications. Understanding these differences aids in efficient system design.

For instance, ball valves are widely used for on/off control. Their quick operation saves time. However, they may not be ideal for flow regulation. Globe valves are a better choice for throttling. They maintain flow even under high pressure. Yet, they can be less efficient compared to other types.

Butterfly valves offer a lightweight option. They excel in large pipelines. Their compact design optimizes space. But they may struggle with tight sealing under certain conditions. This can lead to leakage issues. Each valve type presents advantages and challenges. Recognizing these nuances can lead to better decision-making in fluid management.

Common Applications of Flow Valves in Various Industries

Flow valves play a crucial role in many industries, from manufacturing to pharmaceuticals. They regulate the flow of liquids and gases, ensuring safety and efficiency. According to a recent market analysis, the global valve market is expected to grow by 6.3% annually, highlighting their significance in industrial processes.

In the water treatment sector, flow valves help maintain system pressure. They control the flow rates in pipelines, preventing overflow or low supply. The use of automated flow valves can enhance system transparency. Reports indicate that automated systems reduce operational costs by 20% in long-term projects. However, improper calibration may lead to inefficiencies.

In the oil and gas industry, flow valves manage high-pressure systems. They ensure safe transportation of crude oil and natural gas. Industry surveys show that up to 28% of accidents occur due to valve malfunction. Regular maintenance is vital. Inadequate monitoring can result in catastrophic failures. These examples highlight the need for careful consideration of flow valve applications in various sectors.

Top 10 Flow Valves Types and Their Applications Explained

| Valve Type | Description | Common Applications | Industries |

|---|---|---|---|

| Ball Valve | Offers quick on/off control with minimal pressure drop. | Shut-off service, pipeline isolation. | Oil & Gas, Water Supply |

| Gate Valve | Provides a straight-line flow path with low friction loss. | Isolation in pipelines. | Water, Oil, and Gas |

| Globe Valve | Excellent for throttling and regulating flow. | Flow regulation in various systems. | Chemical, Power Generation |

| Check Valve | Prevents backflow in piping systems. | Backflow prevention. | Water Treatment, HVAC |

| Butterfly Valve | Compact design, ideal for throttling. | Flow control in large pipelines. | Water, Power, Food Industry |

| Pressure Relief Valve | Maintains pressure levels to prevent system failure. | Safety in pressure vessels. | Manufacturing, Chemical Processing |

| Solenoid Valve | Electrically operated, great for automation. | Automated systems and control. | Automotive, Aerospace |

| Diaphragm Valve | Offers a tight seal and excellent for corrosive fluids. | Chemical handling, food processing. | Pharmaceutical, Food |

| Angle Valve | Used for directional flow control. | Cooling systems, steam applications. | HVAC, Power |

| Y-Strainer Valve | Catches debris and protects downstream equipment. | Filtration in piping systems. | Water, Oil, Gas |

Factors to Consider When Selecting Flow Valves

When selecting flow valves, several factors play a crucial role. The type of fluid is paramount. Different fluids have varied properties. For instance, harsh chemicals require specialized materials. You must consider temperature and pressure ratings too. Extreme conditions can lead to valve failure.

Another important aspect is the valve size. Proper sizing ensures optimal flow and prevents issues. Oversized valves may lead to turbulence. This can disrupt flow patterns. Additionally, the valve's response time matters in dynamic systems. A slower valve may cause delays in process control.

Lastly, think about maintenance requirements. Some valves are easier to maintain than others. Complex designs may require more frequent upkeep. You must also consider the installation environment. Space constraints can limit options. Reflecting on these elements will help make the right choice.

Top 10 Flow Valves Types and Their Applications

This chart illustrates the rating of the top flow valve types based on their applications, ranging from 1 to 10. Each valve type plays a significant role in various industrial applications.

Maintenance and Troubleshooting Tips for Flow Valves

Flow valves play a crucial role in managing fluid movement, but they require proper upkeep. Regular maintenance ensures their efficiency and longevity. Check seals and gaskets routinely for any wear. These components are small but vital. A broken seal can lead to leaks.

Keep an eye on the flow rate. If it drops unexpectedly, it may indicate a blockage or a malfunction. Cleaning the valve periodically can prevent issues. Use appropriate cleaning agents to avoid damage. Remember to turn off the system before any maintenance.

When troubleshooting, listen for unusual noises. Strange sounds might suggest internal wear. Act on these signs quickly to avoid further damage. It’s easy to overlook minor issues, but they can snowball. Identifying problems early can save time and money down the line.

Related Posts

-

Understanding Flow Valves: How They Optimize Fluid Control with 30% Efficiency Gains in Industry

-

The Ultimate Guide to Understanding Steel Flanges: Types, Uses, and Industry Insights

-

Exploring Steel and Fittings Trends at the 138th Canton Fair in 2025

-

10 Essential Tips for Choosing the Right Needle Valves for Your Projects

-

What is Steel and Fittings A Comprehensive Guide to Types and Uses

-

7 Best Butterfly Valves for Enhanced Industrial Performance in 2024