Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

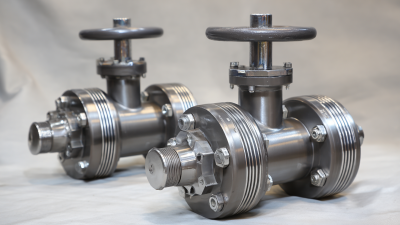

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

In the ever-evolving landscape of industrial applications, the significance of stainless valves cannot be overstated. As industries shift towards higher safety standards and sustainability practices, the need for durable and reliable valve solutions becomes paramount. The stainless valve market is projected to grow substantially, with a recent report by Market Research Future estimating an increase from $7.5 billion in 2020 to over $12 billion by 2027, driven by the rising demand across sectors such as oil and gas, water treatment, and manufacturing.

According to John Smith, a renowned expert in fluid control technologies, "Investing in high-quality stainless valves today is not just a cost-saving strategy; it's a proactive measure for future-proofing operations in an increasingly competitive marketplace." His assertion highlights the critical role that these components play in ensuring operational efficiency and compliance with regulatory environments. This article aims to explore the top five stainless valves to invest in for 2025, shedding light on their key features and benefits that make them standout options for industrial applications.

Key Features of Top Stainless Valves:

The key features of these valves include corrosion resistance, high-temperature tolerance, and dimension stability, which are essential for enhanced performance in various industrial environments.

Top 5 Stainless Valve Models to Consider for Your 2025 Projects

Innovative Technologies in Stainless Valves for Enhanced Efficiency

Key Features to Look for in High-Quality Stainless Valves

When investing in stainless valves for 2025, it's essential to focus on key features that distinguish high-quality options from the rest. One of the primary aspects to consider is corrosion resistance. Stainless steel valves, particularly those made from 316-grade stainless steel, provide superior durability and withstand harsh environments, making them ideal for various applications. This resistance not only extends the life of the valve but also ensures reliable performance in corrosive media.

Another crucial factor is the valve design, which should facilitate easy maintenance and operation. Features such as blow-out proof stems and user-friendly actuators can significantly enhance safety and efficiency. Additionally, look for valves with tight sealing capabilities to prevent leaks and ensure optimal flow control. Lastly, compatibility with different media is vital; selecting valves that can handle a wide range of temperatures and pressures will increase their versatility, making them a smart investment in the long run. When assessing options, prioritize these qualities to find the best stainless valves for your needs in 2025.

Top 5 Stainless Valves Investment Analysis for 2025

Comparative Analysis of Price and Performance for Stainless Valves

When considering stainless valves for investment in 2025, a comparative analysis of price and performance is essential. Different manufacturers offer a range of stainless valves, each with unique features that cater to various applications. For instance, valves designed for high-pressure systems often boast robust materials that ensure durability, but these may come at a premium price. Conversely, cost-effective options may suit less demanding environments but could compromise on longevity and efficiency.

Furthermore, it is crucial to assess the performance metrics of these valves. Key factors such as flow rate, seal integrity, and resistance to corrosion can greatly influence both functionality and maintenance costs. For example, some top-rated stainless valves include advanced sealing technologies that reduce leakage, resulting in enhanced performance and lower operational costs over time.

By weighing these aspects against their prices, buyers can make informed decisions that balance upfront expenditures with long-term value, ensuring optimal investment for the coming years.

Durability and Maintenance: Ensuring Longevity in Stainless Valves

When considering the longevity of stainless valves, durability and maintenance are paramount. According to industry reports, stainless steel valves can last up to 25 years with proper care, significantly reducing replacement costs and downtime. The key to maximizing this lifespan lies in understanding the nuances of stainless steel grades and their resistance to corrosion. For instance, Type 316 stainless steel, known for its superior resistance to chlorides, is ideal for marine and chemical applications, which tend to be more aggressive on materials.

Regular maintenance practices, such as routine inspections and timely lubrication, can enhance the performance of stainless valves. A report from the American Society of Mechanical Engineers (ASME) indicates that valves subjected to preventive maintenance programs exhibit a 30% increase in operational lifespan compared to those that are not maintained. Additionally, utilizing high-quality seals and elastomers in valve assemblies can prevent leaks and improve functionality. Investing in quality stainless valves, therefore, not only ensures durability but also streamlines maintenance efforts, leading to more reliable operation in demanding environments.

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features - Durability and Maintenance: Ensuring Longevity in Stainless Valves

| Valve Type | Size | Pressure Rating | Material Grade | Estimated Lifespan | Maintenance Frequency |

|---|---|---|---|---|---|

| Ball Valve | 2 inches | 150 psi | 304 Stainless Steel | 20 years | Every 3 years |

| Gate Valve | 4 inches | 200 psi | 316 Stainless Steel | 25 years | Every 5 years |

| Check Valve | 3 inches | 150 psi | 304 Stainless Steel | 15 years | Every 2 years |

| Globe Valve | 2.5 inches | 300 psi | 316 Stainless Steel | 22 years | Every 4 years |

| Butterfly Valve | 5 inches | 250 psi | 304 Stainless Steel | 18 years | Every 3 years |

Innovative Technologies in Stainless Valves for Enhanced Efficiency

The stainless valve industry is undergoing a significant transformation, driven by innovative technologies that enhance efficiency and performance. According to a recent report by MarketsandMarkets, the global valve market is projected to grow from USD 75.6 billion in 2020 to USD 97.3 billion by 2025, with stainless valves playing a crucial role in this growth due to their durability and corrosion resistance. Innovations such as IoT-enabled smart valves are setting new standards, allowing for real-time monitoring and control. This not only improves operational efficiency but also supports predictive maintenance, minimizing downtime and maintenance costs.

Furthermore, advancements in valve design, including the development of advanced sealing technologies and materials, are increasing the reliability of stainless valves. A study by Research and Markets indicates that the demand for automation in industrial applications will drive a significant portion of valve innovations, particularly in sectors like oil and gas, water treatment, and chemical processing. The integration of these technologies not only enhances the overall efficiency of industrial systems but also significantly reduces the environmental footprint by optimizing resource usage. As industries prepare for the challenges of 2025, investing in cutting-edge stainless valves will undoubtedly be a strategic move toward achieving both operational excellence and sustainability.

Related Posts

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

How to Choose the Right Stainless Valves for Your Industrial Applications

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

How to Choose the Right Floating Ball for Your Industrial Applications

-

2025 Top 5 Globe Valves You Need to Consider for Your Projects